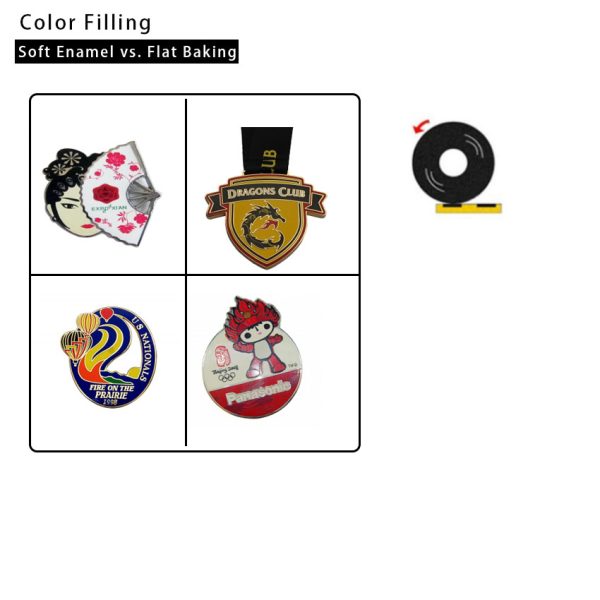

What’s the Difference Between Soft Enamel and Flat Baking in Metal Badge Custom?

When customizing metal badges, two popular finishing options stand out: soft enamel and flat baking. Both deliver sleek, rounded surfaces, but they differ in texture, durability, and application. Let’s break down their key distinctions to help you choose the right finish for your metal badges custom.

1. Surface Texture & Finish

• Soft Enamel:

Produces a smooth, rounded surface with a ceramic-like texture. The color paste is embedded into recessed areas, creating a subtle 3D effect (though less pronounced than traditional hard enamel). It accepts all types of plating (e.g., gold, silver, nickel) and can be filled with vibrant color pastes for bold, long-lasting designs.

• Flat Baking:

Features a smooth, rounded surface with a thin transparent PA (polyamide) coating. This coating acts as a protective layer, enhancing durability while maintaining a flat, matte appearance. The surface lacks the slight texture of soft enamel but offers a cleaner, more uniform look.

2. Production Process

• Soft Enamel:

Color paste is applied to recessed areas of the metal badge. After drying, the badge is polished using a cylindrical buffer to level the metal with the color paste—resulting in a flush, seamless surface with no visible ridges.

• Flat Baking:

The design is printed or coated onto the metal, followed by a transparent PA layer that’s baked to cure. This process skips the polishing step, preserving a flatter profile compared to soft enamel.

3. Durability & Applications

• Soft Enamel:

Best for bold, colorful designs where a slight 3D effect enhances visual appeal. The ceramic-like surface resists wear, making it ideal for high-touch items like metal badges custom for events, brands, or collectibles.

• Flat Baking:

Prioritizes a sleek, modern aesthetic. The PA coating adds scratch resistance, suitable for minimalist or elegant metal badges custom (e.g., corporate logos, awards) where a flat finish is preferred.

Core Keyword Focus: Metal Badges Custom

Whether you choose soft enamel or flat baking for your metal badges custom, both options deliver durability and style. Soft enamel shines with vibrant, textured colors, while flat baking offers a smooth, protective finish. Select based on your design goals—bold visuals or understated elegance.

FAQ

Q: Which is better for detailed designs: soft enamel or flat baking?

A: Soft enamel works well for small, intricate details due to its recessed color application. Flat baking is ideal for large, minimalist patterns where a flat surface avoids color bleeding.

Q: Can both finishes be plated?

A: Yes—soft enamel supports plating (gold, silver, etc.), while flat baking’s PA coating can also be plated for added durability.

Q: Are soft enamel and flat baking water-resistant?

A: Both are water-resistant, but soft enamel’s color paste may fade faster with prolonged exposure to moisture. Flat baking’s PA coating offers better water resistance.

Q: What’s the minimum order for custom metal badges?

A: We accept orders as low as 100 units for soft enamel and 200 units for flat baking—flexible to match your budget.

Q: Do you provide free samples?

A: Yes, we offer free samples (5-10 units) to confirm color, finish, and quality before bulk production.