Custom novelty badges represent a unique intersection of artistic expression, brand identity, and manufacturing excellence. In today’s competitive promotional products market, these specialized badges serve as powerful tools for entertainment companies, organizations, and collectors seeking distinctive memorabilia that captures the essence of memorable experiences. The Blue Man Group official badge exemplifies the pinnacle of custom novelty badge craftsmanship, demonstrating how meticulous attention to detail, premium materials, and innovative manufacturing processes can transform simple zinc alloy into compelling collectible art pieces.

custom novelty badges01

Understanding Custom Novelty Badges in Modern Manufacturing

The custom novelty badges industry has experienced significant evolution, particularly with technological advancements and automation becoming central to growth, with the global button badge machine market projected to reach USD 206.6 million by 2032. Modern manufacturing approaches emphasize precision, durability, and aesthetic appeal, making custom badges essential tools for brand recognition and community building.

Custom novelty badges differ fundamentally from traditional promotional items through their emphasis on artistic design, premium materials, and sophisticated manufacturing techniques. These badges serve multiple functions: they act as collectible memorabilia, brand ambassadors, conversation starters, and symbols of belonging within specific communities or fandoms.

custom novelty badges02

The Blue Man Group Badge: A Case Study in Premium Manufacturing

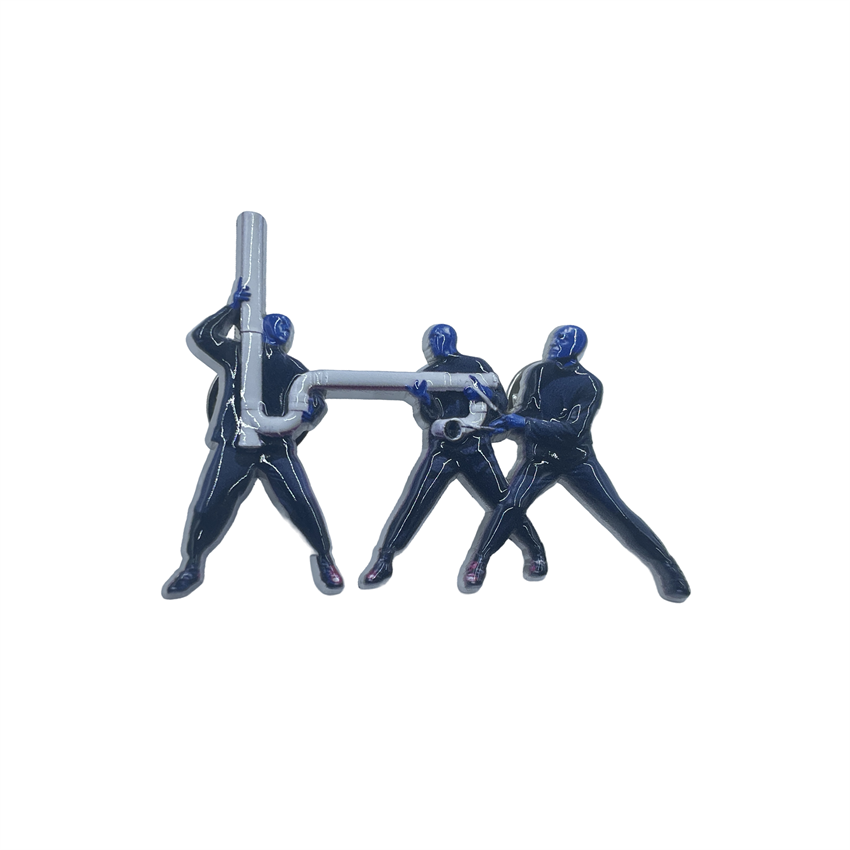

The Blue Man Group official badge represents exceptional craftsmanship in custom novelty badge production. Measuring 55×45×5mm and constructed from high-quality zinc alloy, this badge demonstrates how entertainment IP can be successfully translated into tangible collectible merchandise. The manufacturing process incorporates UV printing technology, ensuring vibrant color reproduction and long-lasting durability that withstand daily wear and environmental factors.

Material Excellence: Zinc Alloy Foundation

Zinc alloy serves as the optimal material choice for premium custom novelty badges due to its exceptional properties. This metallic composition offers superior durability compared to plastic alternatives while maintaining cost-effectiveness relative to precious metals. The zinc alloy construction provides excellent detail retention during the die-casting process, enabling manufacturers to achieve intricate design elements that capture the essence of complex artistic concepts.

The Blue Man Group badge utilizes zinc alloy’s natural properties to create a substantial, professional-feeling product that conveys quality to users. The material’s inherent resistance to corrosion ensures long-term preservation of the badge’s appearance, making it suitable for both casual wear and serious collecting purposes.

Advanced UV Printing Technology

The implementation of UV printing technology in custom novelty badge production represents a significant advancement in manufacturing capabilities. This process enables precise color reproduction, sharp detail definition, and enhanced durability compared to traditional printing methods. UV printing creates a protective layer that resists fading, scratching, and general wear, ensuring that the badge maintains its vibrant appearance throughout its lifespan.

For the Blue Man Group badge, UV printing technology captures the distinctive blue coloration that defines the brand while accurately reproducing the intricate details of the pipe instruments and dynamic poses that characterize the performance group’s visual identity.

Manufacturing Process Excellence

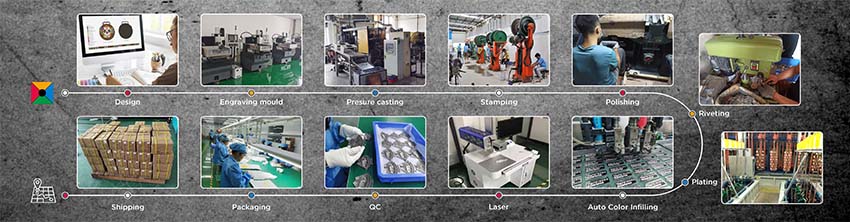

custom process workflow

Badge Artisans Co., Ltd, established in 2010, brings over a decade of specialized experience to custom novelty badge production. The company’s comprehensive manufacturing process demonstrates industry-leading standards through its integration of multiple certified production methodologies.

Design and Prototyping

The manufacturing process begins with professional design services provided by Badge Artisans’ experienced design team. Custom novelty badges require careful consideration of visual hierarchy, brand consistency, and manufacturing constraints. The Blue Man Group badge exemplifies successful design translation, converting three-dimensional performance elements into compelling two-dimensional representations that maintain the original concept’s energy and recognition value.

Professional designers work closely with clients to ensure that custom badges accurately represent intended brand messages while optimizing designs for manufacturing efficiency. This collaborative approach results in products that satisfy both aesthetic and functional requirements.

Precision Manufacturing Steps

Badge Artisans employs a comprehensive production workflow that includes computer mold designing, laser cutting, mold engraving, die stamping, die casting, polishing, plating, welding, riveting, manual and automatic coloring, UV printing, quality control, packaging, and transportation. Each step undergoes strict quality control measures to ensure consistent output quality.

The die-casting process creates the basic badge shape and relief details, while subsequent finishing operations add color, texture, and protective coatings. The dual butterfly clasp attachment system provides secure wearing options while maintaining professional appearance standards.

Industry Trends and Innovations in 2025

The custom novelty badge industry continues evolving with personalization standing out as a key differentiator, while intelligent and interactive badges with NFC or RFID technology offer enhanced functionality beyond recognition. These technological integrations represent opportunities for entertainment properties like Blue Man Group to create more engaging fan experiences through interactive merchandise.

Sustainability Considerations

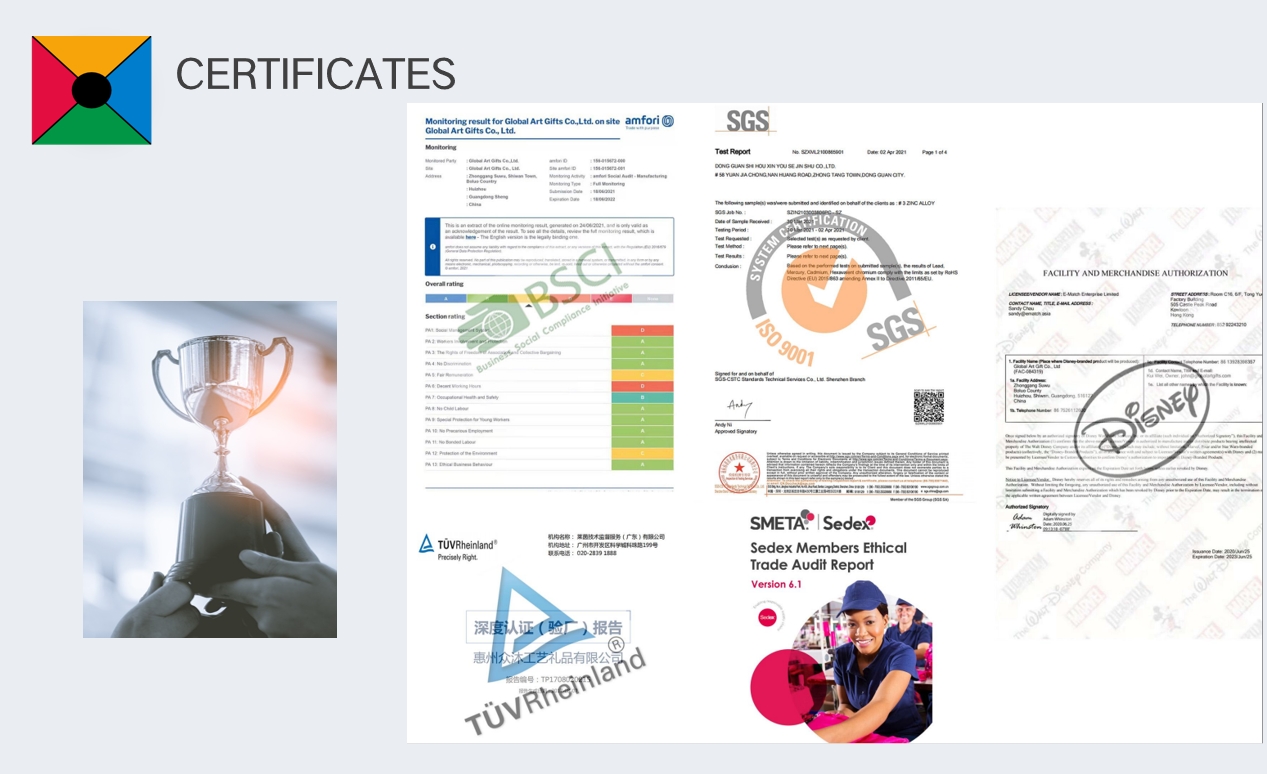

Modern custom badge manufacturing increasingly emphasizes environmental responsibility through material selection, production efficiency, and waste reduction strategies. Badge Artisans’ certified production facility demonstrates commitment to sustainable practices through TÜV Rheinland, Disney, BSCI, and Sedex certifications, ensuring responsible manufacturing that meets international environmental and social standards.

Customization Capabilities

The adoption of 3D printing technology enables the creation of highly intricate and personalized badges at lower costs, while integration of smart technologies enhances functionality and appeal. These advances enable manufacturers to offer increasingly sophisticated customization options for entertainment properties and corporate clients seeking unique promotional products.

Market Applications and Target Demographics

Custom novelty badges serve diverse market segments, from entertainment merchandise to corporate promotional products. The Blue Man Group badge specifically targets several key demographics: live performance attendees seeking memorabilia, collectors of entertainment merchandise, artistic expression enthusiasts, and Blue Man Group brand advocates.

Entertainment Industry Applications

Entertainment properties benefit significantly from custom novelty badges as revenue-generating merchandise that extends brand engagement beyond primary experiences. The Blue Man Group badge serves as a portable reminder of the live performance experience, enabling fans to display their connection to the artistic community while potentially introducing the brand to new audiences through social interaction.

Corporate and Promotional Uses

Organizations increasingly utilize custom novelty badges for employee recognition, brand promotion, and community building initiatives. The manufacturing techniques demonstrated in the Blue Man Group badge application can be adapted for corporate logos, achievement recognition, and special event commemoration.

Quality Assurance and Certification Standards

Professional custom novelty badge manufacturing requires adherence to strict quality standards and international certifications. Badge Artisans’ comprehensive certification portfolio, including TÜV Rheinland, Disney, BSCI, and Sedex approvals, demonstrates commitment to manufacturing excellence and responsible business practices.

International Compliance

Manufacturing custom badges for global distribution requires understanding and compliance with various international standards regarding materials, production methods, and safety requirements. Badge Artisans’ certification portfolio enables confident distribution across North America, Europe, Asia, and Australia markets.

Quality Control Processes

Rigorous quality control throughout the manufacturing process ensures consistent output quality and customer satisfaction. Each Blue Man Group badge undergoes multiple inspection points to verify dimensional accuracy, color consistency, attachment security, and overall finish quality before packaging and shipment.

Design Considerations for Effective Custom Novelty Badges

Successful custom novelty badge design requires balancing artistic vision with manufacturing constraints and user preferences. The Blue Man Group badge exemplifies effective design translation through its careful adaptation of three-dimensional performance elements into two-dimensional badge format while maintaining brand recognition and artistic impact.

Visual Hierarchy and Brand Recognition

Effective badge design establishes clear visual hierarchy that guides viewer attention while ensuring brand recognition at various viewing distances. The Blue Man Group badge achieves this through strategic use of contrasting colors, distinctive silhouettes, and recognizable symbolic elements that immediately communicate brand identity.

Manufacturing Optimization

Design optimization for manufacturing efficiency reduces production costs while maintaining quality standards. Considerations include color limitations, detail complexity, attachment methods, and material utilization efficiency. Professional design services ensure that creative vision aligns with manufacturing capabilities and budget constraints.

Future Developments in Custom Badge Manufacturing

The custom novelty badge industry continues evolving through technological advancement, materials innovation, and changing consumer preferences. Recent forecasts predict significant growth in the global market with a compound annual growth rate of 10.48% from 2025 to 2029, indicating strong market demand for innovative badge products.

Technology Integration

Future developments may include enhanced NFC capabilities, augmented reality features, and sustainable material alternatives that maintain quality while reducing environmental impact. These innovations will enable entertainment properties to create more engaging and environmentally responsible merchandise offerings.

Market Expansion Opportunities

Growing demand for personalized and collectible merchandise creates opportunities for expansion into new market segments and geographic regions. The success of products like the Blue Man Group badge demonstrates market appetite for high-quality entertainment merchandise that extends brand experiences beyond primary entertainment venues.

Conclusion: Excellence in Custom Novelty Badge Manufacturing

Custom novelty badges represent sophisticated manufacturing achievements that combine artistic vision, technical expertise, and market understanding. The Blue Man Group official badge exemplifies how professional manufacturers like Badge Artisans Co., Ltd can successfully translate complex entertainment properties into compelling collectible merchandise through careful attention to material selection, manufacturing processes, and design optimization.

As the industry continues evolving through technological advancement and changing consumer preferences, manufacturers who maintain focus on quality, innovation, and customer satisfaction will continue leading market development. The combination of traditional craftsmanship with modern manufacturing technology creates opportunities for producing custom novelty badges that exceed customer expectations while building lasting brand connections.

For organizations seeking premium custom novelty badges that reflect their brand values and engage target audiences effectively, partnering with experienced manufacturers who demonstrate comprehensive capabilities, international certifications, and commitment to excellence ensures successful project outcomes. The Blue Man Group badge serves as an inspiring example of what becomes possible when creative vision meets manufacturing expertise in the dynamic custom badge industry.

Whether for entertainment merchandise, corporate recognition, or special event commemoration, custom novelty badges continue proving their value as effective tools for brand building, community engagement, and memorable experience creation. The future of this industry promises continued innovation and growth as manufacturers embrace new technologies while maintaining the craftsmanship standards that define premium badge production.

Badge Artisans Co., Ltd specializes in premium custom novelty badges manufacturing with comprehensive design services, international certifications, and global distribution capabilities. Contact us to discuss your custom badge requirements and discover how professional manufacturing expertise can bring your brand vision to life through exceptional badge products.