Introduction

Custom shaped challenge coins have evolved far beyond traditional circular designs, offering organizations, military units, law enforcement agencies, and corporate teams unique opportunities to create memorable tokens of recognition. At Badge Artisans Co., Ltd, we specialize in manufacturing premium custom shaped challenge coins using advanced zinc alloy die-cast technology, delivering exceptional quality that meets the highest industry standards. Our expertise in coin design, coupled with state-of-the-art manufacturing processes, ensures that each custom challenge coin becomes a treasured symbol of achievement and belonging.

Challenge coins serve as powerful symbols of camaraderie, recognition, and organizational pride. When crafted in custom shapes, these commemorative pieces take on even greater significance, allowing organizations to incorporate their unique logos, emblems, or meaningful symbols directly into the coin’s silhouette. Our custom shaped challenge coins represent the perfect fusion of traditional craftsmanship and modern manufacturing technology, creating distinctive pieces that stand apart from standard offerings in the market.

|

|

The Art and Science of Custom Shaped Challenge Coins

Understanding Custom Challenge Coin Design

Custom shaped challenge coins break free from the constraints of traditional round designs, opening up endless possibilities for creative expression. These specialized coins can be crafted to match specific organizational emblems, company logos, or symbolic representations that hold special meaning for the recipients. The process begins with understanding the client’s vision and translating that concept into a manufacturable design that maintains structural integrity while maximizing visual impact.

The design process for custom shaped challenge coins requires careful consideration of several factors. First, the complexity of the desired shape must be balanced against manufacturing feasibility. While our advanced zinc alloy die-cast processes can accommodate intricate details and complex geometries, certain design elements may require modification to ensure optimal production results. Our experienced design team works closely with clients to refine their concepts, ensuring that the final design captures their vision while meeting practical manufacturing requirements.

Size and shape considerations play a crucial role in the success of custom challenge coin projects. Unlike standard round coins that rely on diameter measurements, custom shaped challenge coins are typically specified by their maximum dimensions. A coin measuring 50mm x 50mm x 3mm, for example, provides ample space for detailed artwork while maintaining comfortable handling characteristics. The 3mm thickness ensures durability while allowing for sufficient depth in raised and recessed design elements.

Material Selection: Why Zinc Alloy Excels for Custom Shapes

The choice of zinc alloy as the base material for custom shaped challenge coins reflects our commitment to quality and manufacturing efficiency. Zinc alloy is injected under high pressure during the die-casting process, cooling and solidifying to create strong, durable products that retain fine details and 3D features. Compared with brass challenge coins which are die-stamped piece by piece, zinc alloy challenge coins can be done in large quantities in a fairly short amount of time, making them cost-effective with better freight advantages due to their lighter weight.

Zinc alloy offers several distinct advantages for custom shaped challenge coins. Its low melting point (approximately 419°C) allows for excellent flow characteristics during the die-casting process, ensuring that even the most intricate design details are captured accurately. The material’s strength-to-weight ratio makes it ideal for coins that will be handled frequently, while its corrosion resistance ensures long-term durability. Additionally, zinc alloy accepts various plating and finishing options beautifully, allowing for diverse aesthetic treatments.

The die-casting process used with zinc alloy enables the creation of coins with complex three-dimensional features that would be impossible or prohibitively expensive to achieve through traditional stamping methods. The die-casting process allows coins to be up to 5mm thick, with vivid colors hand-filled in the recessed areas using the cloisonné-B process. This flexibility in thickness and detail makes zinc alloy the preferred choice for custom shaped challenge coins that require exceptional visual impact.

Manufacturing Excellence: The Badge Artisans Advantage

Advanced Production Capabilities

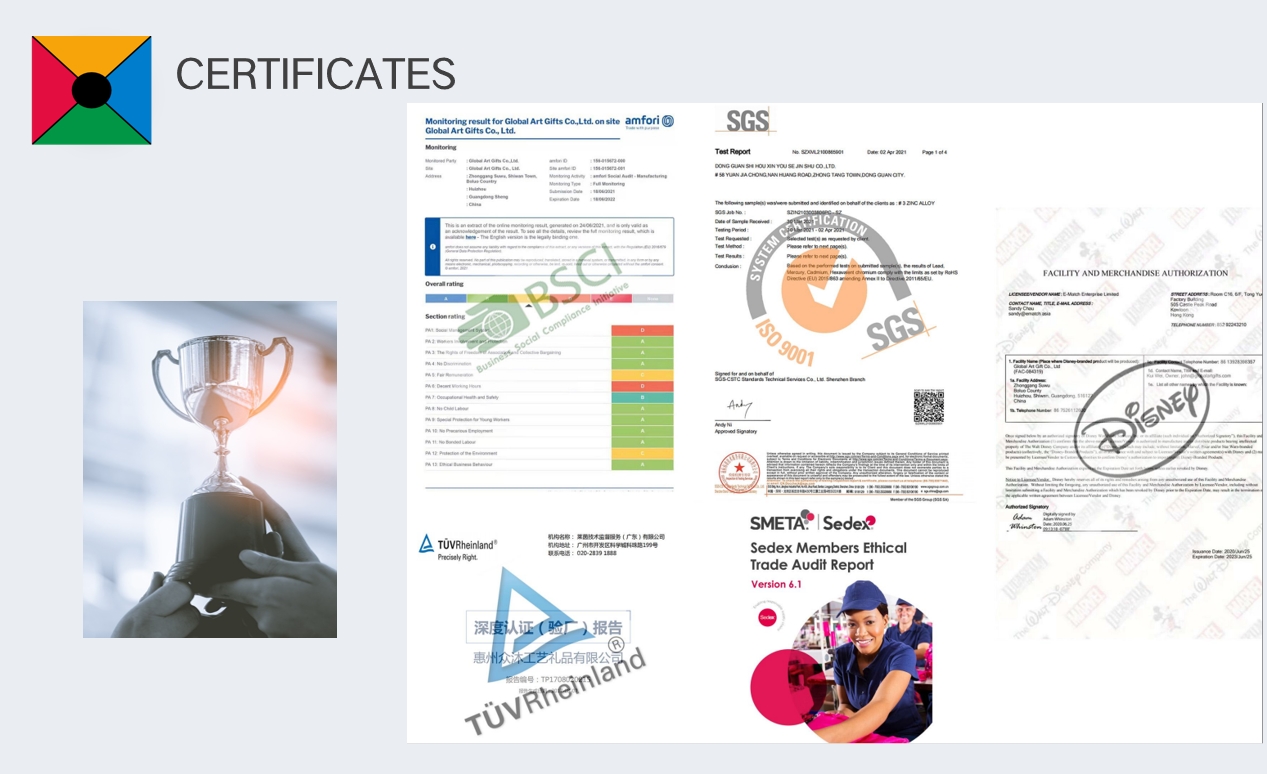

Badge Artisans Co., Ltd brings over a decade of experience to the challenge coin manufacturing industry. Founded in 2010, our company has established itself as a leader in the production of high-quality promotional items, with challenge coins representing one of our core specialties. Our facility has earned certifications from TÜVRheinland, Disney, BSCI, and Sedex, demonstrating our commitment to quality, safety, and ethical manufacturing practices.

Our production capabilities encompass the complete challenge coin manufacturing process. Beginning with computer-aided mold design, we utilize advanced CAD software to create precise digital models of custom shaped challenge coins. These digital designs serve as the foundation for creating the steel dies used in the casting process. Our laser engraving and mold engraving capabilities ensure that every detail specified in the original design is accurately reproduced in the final product.

The die-casting process itself represents the heart of our manufacturing operation. Die cast molds are fit together and molten zinc metal is injected into the die to create the coin blank. Our hydraulic die-casting machines operate with precision-controlled pressure and temperature parameters, ensuring consistent results across entire production runs. Quality control checkpoints throughout the process verify dimensional accuracy, surface finish quality, and conformance to specification.

Comprehensive Manufacturing Process

Our complete production flow encompasses every step required to transform a concept into a finished custom shaped challenge coin. The process begins with computer mold designing, where our engineering team creates detailed 3D models that account for both aesthetic requirements and manufacturing constraints. These models undergo rigorous review to identify potential issues before expensive tooling is created.

Mold engraving follows, utilizing both traditional machining techniques and modern CNC equipment to create the precision dies required for consistent production. The quality of these dies directly impacts the final product’s appearance and dimensional accuracy. Our experienced toolmakers ensure that each die meets exacting standards before proceeding to production.

The die-casting phase involves injecting molten zinc alloy into the closed dies under high pressure. This process captures even the finest details of the original design while ensuring complete fill of complex shapes. Following casting, each coin undergoes careful removal from the outlet system and initial quality inspection.

Post-casting operations include polishing to achieve the desired surface finish, followed by plating to apply the specified metal finishes. Our plating capabilities include various gold, silver, copper, and specialty finishes that enhance the coin’s appearance and provide corrosion protection. For coins requiring color applications, we employ both manual and automatic coloring processes, ensuring consistent coverage and vibrant color reproduction.

UV printing capabilities allow us to apply full-color graphics directly to the coin surface, enabling photographic reproductions and complex color schemes that traditional enamel processes cannot achieve. This technology is particularly valuable for custom shaped challenge coins that require corporate logos or detailed imagery.

Color Spraying and Finishing Techniques

Advanced Color Application Methods

The color spraying process used on our custom shaped challenge coins represents a sophisticated approach to achieving vibrant, durable finishes. Unlike traditional enamel filling, color spraying allows for smooth, even coverage across complex three-dimensional surfaces. This technique is particularly advantageous for custom shaped challenge coins where traditional enamel application might be challenging due to unusual geometries or fine details.

Our color spraying process begins with thorough surface preparation. Each coin is cleaned and primed to ensure optimal adhesion of the color coatings. The spraying itself is performed in controlled environments to prevent contamination and ensure consistent color matching. Multiple thin coats are applied rather than single thick applications, resulting in superior durability and finish quality.

The color spraying technique excels at creating smooth gradients and complex color transitions that would be difficult to achieve through other methods. This capability is particularly valuable for custom shaped challenge coins that incorporate brand colors or specific color schemes. The process also allows for the application of special effect finishes, including metallic accents and textured surfaces.

Quality control during the color spraying process involves continuous monitoring of color consistency, coverage uniformity, and finish quality. Each batch is compared against approved color standards to ensure that the final products match the client’s specifications exactly. Post-spray inspection identifies any defects that require correction before the coins proceed to final packaging.

Surface Treatment and Finishing Options

Beyond basic color application, our finishing capabilities include numerous surface treatments that enhance both the appearance and durability of custom shaped challenge coins. Polishing operations range from high-gloss mirror finishes to subtle satin textures, each selected to complement the overall design aesthetic. The choice of finish significantly impacts the final appearance of the coin and its perceived value.

Plating options provide both protective and decorative benefits. Gold plating, available in various karat levels, offers a premium appearance suitable for high-value recognition programs. Silver plating provides a classic, timeless look while offering excellent corrosion resistance. Copper and brass platings deliver warm, traditional appearances that complement certain design themes.

Antique finishes create the appearance of aged metals, adding character and sophistication to custom shaped challenge coins. These finishes are particularly popular for military challenge coins and commemorative pieces where a sense of history and tradition is important. The antiquing process involves controlled oxidation followed by selective polishing to create depth and visual interest.

Specialty finishes include sandblasting for textured surfaces, laser engraving for precise detail work, and various protective coatings that enhance durability in challenging environments. Each finishing option is selected based on the intended use of the coins and the aesthetic goals of the project.

Applications and Market Segments

Military Challenge Coins

Military challenge coins represent perhaps the most traditional application for custom shaped challenge coins. These coins serve multiple purposes within military organizations, from unit identification to recognition of exceptional service. Custom shapes allow military units to incorporate their distinctive emblems, insignia, or symbolic elements directly into the coin’s silhouette, creating immediately recognizable tokens of unit pride.

The tradition of military challenge coins dates back decades, with origins often attributed to World War I aviators. Today, these coins play important roles in building unit cohesion, recognizing achievement, and maintaining connections among service members. Custom shaped challenge coins elevate this tradition by creating unique pieces that cannot be confused with standard issue items.

Design considerations for military challenge coins often include incorporation of official unit crests, national symbols, or mission-specific imagery. The custom shape itself might represent the unit’s role or equipment, such as aircraft silhouettes for aviation units or specialized shapes for particular military occupations. Security considerations sometimes influence design choices, with certain details modified to prevent unauthorized reproduction.

Production requirements for military challenge coins often include specific material certifications and finish durability standards. Our manufacturing processes meet or exceed these requirements, ensuring that each coin represents the quality and professionalism associated with military service. Special packaging options are available for presentation purposes or long-term storage.

Law Enforcement Agencies

Law enforcement agencies increasingly recognize the value of custom shaped challenge coins for building morale, recognizing exceptional service, and strengthening community relationships. These coins often incorporate badge shapes, department emblems, or symbols representing specific law enforcement functions. The custom shape capability allows departments to create coins that instantly identify their organization and convey their values.

Police challenge coins serve various functions within law enforcement organizations. They recognize officers for exceptional performance, commemorate special operations or significant cases, and build bridges with community organizations. Custom shaped challenge coins make these recognition programs more memorable and meaningful by creating unique pieces that recipients will treasure.

Design elements for law enforcement challenge coins frequently include department badges, American flags, scales of justice, or other symbols of law and order. The thin blue line concept appears regularly in these designs, often implemented through color choices or graphic elements. Custom shapes might represent the jurisdiction’s boundaries, local landmarks, or specialized equipment used by the department.

Special considerations for law enforcement challenge coins include durability requirements for daily carry and professional appearance standards that reflect the dignity of police service. Our manufacturing processes produce coins that meet these demanding requirements while maintaining the visual impact necessary for effective recognition programs.

Corporate Challenge Coins

Corporate adoption of challenge coin traditions has grown significantly as businesses recognize their value for employee recognition, team building, and brand promotion. Custom shaped challenge coins offer corporations unique opportunities to create memorable tokens that reinforce company values, celebrate achievements, and build organizational culture. The custom shape capability allows direct incorporation of company logos or brand elements into the coin’s design.

Corporate challenge coins serve numerous business purposes. They recognize employee achievements, commemorate project completions, celebrate company milestones, and reinforce corporate culture. Sales teams often use them as unique business cards or client gifts that create lasting impressions. The tangible nature of challenge coins makes them more memorable than traditional recognition items.

Design considerations for corporate challenge coins focus on brand consistency and professional appearance. Company logos, brand colors, and corporate messaging are typically incorporated into the design. Custom shapes might represent product silhouettes, company symbols, or abstract forms that convey corporate values. The overall aesthetic should reflect the company’s professional image while creating emotional connections with recipients.

Quality expectations for corporate challenge coins often exceed those for other applications due to their role in representing the company brand. Recipients may include high-value clients, key employees, or important partners, making quality paramount. Our manufacturing processes ensure that each coin reflects the professionalism and attention to detail that corporations demand.

Design Innovation and Customization Options

Creative Shape Possibilities

The realm of custom shaped challenge coins offers virtually unlimited creative possibilities, bounded only by manufacturing feasibility and practical considerations. Our design team regularly works with clients to explore innovative shapes that capture their organization’s essence while maintaining structural integrity and visual appeal. The key lies in balancing creativity with functionality to create coins that are both striking and practical.

Geometric shapes provide clean, modern aesthetics that work well for contemporary organizations. Squares, triangles, hexagons, and other geometric forms can be modified with rounded corners, cutouts, or dimensional variations to create unique silhouettes. These shapes often work well for technology companies, engineering firms, or organizations with modern brand identities.

Organic shapes inspired by natural forms offer opportunities for more artistic expression. Leaf shapes for environmental organizations, animal silhouettes for wildlife groups, or geographical outlines for location-specific entities create immediate visual connections between the coin and its purpose. The challenge lies in simplifying complex organic forms while maintaining their recognizable characteristics.

Symbolic shapes draw directly from organizational emblems, logos, or meaningful icons. Badge shapes for law enforcement, cross shapes for medical organizations, or tool silhouettes for trade organizations create instant recognition and connection. These shapes often require careful engineering to ensure structural stability while preserving symbolic accuracy.

Dimensional Design Elements

Custom shaped challenge coins can incorporate various dimensional elements that add visual interest and tactile appeal. Raised and recessed areas create depth and shadow effects that enhance the overall design impact. The interplay between different height levels allows designers to emphasize important elements while creating visually dynamic compositions.

Cutout areas within custom shaped challenge coins create unique visual effects and can serve functional purposes. Bottle opener cutouts, for example, transform decorative coins into practical tools while maintaining their symbolic value. Window cutouts can frame internal design elements or create interesting shadow patterns. Each cutout must be carefully engineered to maintain structural integrity while achieving the desired visual effect.

Edge treatments provide additional opportunities for customization. Rope edges, gear edges, or custom-designed edge patterns can complement the overall design theme while adding sophisticated finishing touches. The edge treatment often provides the first tactile impression when someone handles the coin, making it an important element in the overall user experience.

Three-dimensional sculptural elements can be incorporated into custom shaped challenge coins to create truly unique pieces. Relief sculptures, architectural details, or miniature representations of significant objects add artistic value while creating strong emotional connections. These elements require careful consideration of manufacturing capabilities and cost implications.

Integration of Technology and Traditional Craftsmanship

Modern custom shaped challenge coins benefit from the integration of advanced technology with traditional metalworking craftsmanship. Computer-aided design software allows for precise visualization of complex shapes and detailed analysis of manufacturing feasibility. 3D modeling capabilities enable clients to see realistic previews of their coins before committing to production.

Laser engraving technology enables the addition of extremely fine details that would be impossible to achieve through traditional methods. Serial numbers, individual names, or intricate patterns can be added with precision accuracy. This capability is particularly valuable for limited edition coins or pieces that require personalization.

Digital printing technologies expand color capabilities beyond traditional enamel limitations. Full-color photographs, complex graphics, or gradient effects can be applied directly to coin surfaces. This technology is especially valuable for commemorative coins that need to reproduce specific images or complex brand graphics.

Traditional craftsmanship techniques continue to play important roles in custom challenge coin production. Hand-finishing operations ensure that each coin meets quality standards, while skilled artisans add final touches that distinguish premium products from mass-produced alternatives. The combination of technology and craftsmanship creates products that honor tradition while embracing innovation.

Quality Assurance and Certification

Manufacturing Standards and Certifications

Badge Artisans Co., Ltd maintains rigorous quality standards throughout the custom shaped challenge coin manufacturing process. Our certifications from TÜVRheinland, Disney, BSCI, and Sedex demonstrate our commitment to quality, safety, and ethical manufacturing practices. These certifications require regular audits and continuous improvement in our processes, ensuring that clients receive products that meet international quality standards.

Quality control begins with incoming material inspection, where all zinc alloy stock is verified for composition, purity, and physical properties. Only materials meeting our strict specifications are accepted for production use. This attention to material quality ensures consistent casting results and final product performance.

Process monitoring occurs at every stage of production, from initial mold design through final packaging. Statistical process control techniques identify variations before they can affect product quality. Regular calibration of equipment ensures that dimensional tolerances are maintained throughout production runs. Temperature and pressure monitoring during die-casting prevents defects related to improper processing conditions.

Final inspection procedures verify that each custom shaped challenge coin meets all specified requirements. Visual inspection identifies surface defects, dimensional verification confirms size and shape accuracy, and functional testing ensures that any special features operate correctly. Only coins passing all inspection criteria are approved for shipment to clients.

International Quality Standards Compliance

Our commitment to international quality standards extends beyond basic manufacturing requirements to encompass environmental responsibility and ethical business practices. BSCI certification verifies our adherence to social compliance standards, ensuring that all workers are treated fairly and that working conditions meet international labor standards. This certification is increasingly important to corporate clients who require supply chain transparency.

Environmental management practices minimize the impact of our manufacturing operations. Waste reduction programs ensure that material usage is optimized, while recycling initiatives capture and reprocess scrap materials. Energy efficiency measures reduce our carbon footprint while maintaining production capabilities. These practices align with the sustainability goals of many of our clients.

Sedex certification provides additional verification of our ethical business practices and supply chain transparency. This certification requires detailed reporting of labor practices, health and safety measures, environmental impact, and business ethics. The resulting transparency enables clients to make informed decisions about their supply chain partnerships.

Disney certification represents one of the most stringent quality and ethical standards in the industry. This certification requires comprehensive audit of all business practices, from manufacturing processes to worker welfare. Maintaining this certification demonstrates our capability to meet the highest industry standards for quality and ethical business practices.

Continuous Improvement and Innovation

Our quality management system emphasizes continuous improvement through regular assessment of processes, customer feedback analysis, and investment in new technologies. Customer satisfaction surveys provide valuable insights into areas for improvement, while production data analysis identifies opportunities for process optimization. This systematic approach to improvement ensures that our capabilities continue to evolve with market demands.

Investment in new technologies maintains our competitive advantage while improving product quality. Recent additions to our equipment lineup include advanced CNC machining centers for mold production, upgraded plating systems for improved finish quality, and enhanced color spraying equipment for better consistency. These investments demonstrate our commitment to providing the best possible products to our clients.

Training and development programs ensure that our workforce maintains the skills necessary for quality production. Regular training sessions cover new technologies, quality requirements, and safety procedures. Skilled craftsmen mentor newer employees, preserving traditional techniques while incorporating modern methods. This investment in human resources is fundamental to our ability to deliver consistent quality.

Research and development activities explore new materials, processes, and design possibilities that can benefit future products. Collaboration with suppliers identifies new alloys, finishes, or treatments that might enhance our capabilities. Customer feedback guides development priorities, ensuring that our innovations address real market needs rather than pursuing technology for its own sake.

Global Market Reach and Customer Service

International Market Presence

Badge Artisans Co., Ltd serves clients across North America, Europe, Asia, and Australia, demonstrating our capability to meet diverse market requirements while maintaining consistent quality standards. Our international market presence reflects both the universal appeal of custom shaped challenge coins and our ability to adapt to different cultural preferences and regulatory requirements.

North American markets represent a significant portion of our business, with particular strength in military, law enforcement, and corporate segments. The rich tradition of challenge coins in American military culture creates steady demand for innovative designs and premium quality. Canadian markets show growing interest in challenge coins for various applications, from commemorative pieces to corporate recognition programs.

European markets appreciate the craftsmanship and attention to detail that characterizes our products. Different countries within Europe have varying preferences for design styles, finishes, and packaging, requiring flexibility in our approach. Compliance with European Union regulations for product safety and environmental impact is carefully maintained through our certification programs.

Asian markets, particularly Japan, value precision manufacturing and innovative design. The attention to detail and quality consistency that characterizes Japanese business culture aligns well with our manufacturing philosophy. Growing interest in Western-style recognition programs creates opportunities for custom shaped challenge coins in corporate and organizational settings.

Australian markets show strong interest in commemorative challenge coins that celebrate local events, achievements, or cultural elements. The country’s military tradition creates demand for high-quality military challenge coins, while growing corporate adoption expands market opportunities. Distance and shipping considerations require careful logistics planning to ensure cost-effective delivery.

Customer Service Excellence

Our customer service philosophy emphasizes partnership rather than simple vendor relationships. We work closely with clients throughout the design and production process, ensuring that their vision is accurately translated into finished products. This collaborative approach builds long-term relationships and ensures customer satisfaction with every project.

Free design services represent a significant value-added offering that distinguishes us from competitors. Our professional design team works with clients to refine their concepts, suggesting improvements that enhance visual impact while ensuring manufacturing feasibility. Multiple design iterations are provided at no charge until the client is completely satisfied with the proposed design.

Communication throughout the production process keeps clients informed of progress and provides opportunities for feedback or modifications. Regular status updates prevent surprises and demonstrate our commitment to transparency. Digital proofs and samples enable clients to verify that their expectations are being met before full production begins.

Technical support extends beyond the initial sale to include guidance on care and maintenance of finished products. Proper storage and handling techniques help ensure that custom shaped challenge coins maintain their appearance over time. When questions arise about specific products or applications, our technical team provides prompt, knowledgeable assistance.

Specialized Applications and Case Studies

Marathon and Sports Event Commemoratives

The 2020 Xiamen Marathon presented an excellent example of how custom shaped challenge coins can commemorate sporting achievements while celebrating local culture. This full marathon finisher’s medal, crafted from zinc alloy using our advanced die-cast processes, demonstrated the perfect integration of athletic recognition with regional identity. The custom shape incorporated flowing oceanic elements that captured Xiamen’s coastal character while clearly marking the achievement of completing the full 42.195-kilometer distance.

The manufacturing process for this commemorative piece utilized our specialized color spraying techniques to achieve the vibrant blue-green gradient that evoked ocean waves. The zinc alloy base provided the structural integrity necessary for the complex curved edges while maintaining a comfortable weight for long-term display. Gold electroplating on central elements added premium visual impact appropriate for such a significant athletic achievement.

Sports organizations worldwide are discovering the value of custom shaped challenge coins for recognizing achievements, building team identity, and creating lasting memories. Unlike traditional medals that follow standard formats, custom shaped challenge coins can incorporate team logos, mascots, or symbolic elements directly into the coin’s silhouette. This capability makes each piece unique and immediately identifiable with its issuing organization.

Educational Institution Recognition Programs

Educational institutions from elementary schools through universities are adopting custom shaped challenge coins for various recognition programs. Academic achievement awards, perfect attendance recognition, graduation commemoratives, and alumni gifts all benefit from the personal touch that custom shapes provide. School mascots, architectural landmarks, or academic symbols can be incorporated into coin designs that create lasting connections between recipients and their institutions.

The durability of zinc alloy construction makes these coins suitable for daily carry by students and staff, while various finish options allow institutions to create pieces that reflect their unique character. Budget-conscious educational institutions particularly appreciate the cost-effectiveness of zinc alloy challenge coins compared to alternatives, allowing recognition programs to reach more deserving recipients.

Design considerations for educational challenge coins often emphasize positive messaging, school colors, and symbols that reinforce institutional values. Custom shapes might represent school buildings, academic tools, or abstract forms that convey educational themes. The goal is creating pieces that recipients will treasure long after their formal education concludes.

Corporate Recognition and Team Building

Modern corporations are embracing custom shaped challenge coins as powerful tools for employee recognition, team building, and corporate culture development. These coins transcend traditional employee awards by creating tangible symbols of achievement that recipients can display with pride. The custom shape capability allows direct incorporation of corporate logos, brand elements, or product representations into the coin design.

Sales achievement programs particularly benefit from custom shaped challenge coins because they create memorable rewards that reinforce company branding. Top performers often display their coins prominently, creating positive peer pressure and motivation among team members. The coins become conversation starters that naturally promote company values and achievements.

Project completion commemoratives use custom shaped challenge coins to recognize team efforts and create lasting memories of significant accomplishments. Unlike certificates that may be filed away, challenge coins maintain visible presence in workspaces, serving as ongoing reminders of successful collaborations and shared achievements.

Employee milestone recognition programs utilize custom shaped challenge coins to celebrate years of service, promotions, or career achievements. These coins create emotional connections between employees and their organizations, potentially improving retention and job satisfaction. The personal nature of custom shapes makes each recognition feel special and individually meaningful.

Market Trends and Future Developments

Growing Demand for Personalization

The market for custom shaped challenge coins continues to expand as organizations recognize their value for creating unique, memorable recognition pieces. Growing demand for personalization drives innovation in design capabilities and manufacturing techniques. Clients increasingly seek coins that tell specific stories, represent unique values, or capture particular moments in organizational history.

Sequential numbering and individual personalization options are becoming more popular as organizations create limited edition coins for special events or exclusive recognition programs. Our manufacturing capabilities accommodate these requirements through advanced laser engraving and digital printing technologies that add individual touches without compromising production efficiency.

Variable data printing enables the creation of coins where each piece contains different information while maintaining consistent base designs. This capability is particularly valuable for event commemoratives where participant names, completion times, or other individual data enhance the personal significance of each coin.

Technological Integration

Modern custom shaped challenge coins increasingly incorporate advanced technologies that extend their functionality beyond traditional commemorative purposes. NFC (Near Field Communication) chips embedded within coins can link to digital content, creating interactive experiences that bridge physical and digital worlds. QR codes laser-engraved on coin surfaces provide similar connectivity while remaining visible to users.

Augmented reality integration allows custom shaped challenge coins to trigger digital experiences when viewed through smartphone apps. These technologies create opportunities for storytelling, additional information sharing, or interactive games that enhance the coin’s value beyond its physical properties. Organizations can use these capabilities for training programs, historical education, or marketing initiatives.

Security features are becoming increasingly important as counterfeit prevention measures. Holographic elements, microtext, or specialized finishes help ensure authenticity while adding visual interest. These features are particularly important for high-value recognition programs or coins that carry official significance.

Sustainable Manufacturing Practices

Environmental consciousness drives demand for sustainable manufacturing practices in custom shaped challenge coin production. Our zinc alloy die-cast processes offer inherent environmental advantages through material recycling capabilities and energy-efficient production methods. Zinc alloy scrap generated during production is completely recyclable, reducing waste and conserving resources.

Packaging innovations focus on reducing environmental impact while maintaining product protection during shipping. Biodegradable packaging materials, minimized packaging volumes, and reusable presentation cases align with corporate sustainability goals. These considerations are increasingly important to environmentally conscious clients.

Local sourcing initiatives reduce transportation impacts while supporting regional suppliers. Our supplier selection criteria include environmental performance evaluations alongside quality and cost considerations. This comprehensive approach ensures that our entire supply chain aligns with sustainability objectives.

Design Guidelines and Best Practices

Effective Shape Selection

Successful custom shaped challenge coins begin with thoughtful shape selection that balances visual impact with practical considerations. The chosen shape should clearly relate to the organization, event, or purpose being commemorated while remaining recognizable at typical viewing distances. Overly complex shapes may lose impact when reduced to coin size, while overly simple shapes may lack distinction.

Aspect ratio considerations ensure that custom shapes work well within typical coin size constraints. Shapes that are too elongated may become fragile or awkward to handle, while those that are too compact may not provide sufficient surface area for necessary design elements. The optimal balance creates shapes that are both visually striking and functionally practical.

Edge considerations play crucial roles in both appearance and durability. Sharp points or thin projections may be vulnerable to damage during handling or storage. Rounded edges and reinforced connection points improve durability while maintaining visual appeal. These engineering considerations must be balanced against design requirements to achieve optimal results.

Color Integration Strategies

Effective color integration in custom shaped challenge coins requires careful consideration of manufacturing capabilities and design objectives. Our color spraying processes enable smooth, even coverage across complex three-dimensional surfaces, but color placement must be planned to ensure accessibility during production. Areas that are difficult to reach during spraying may require alternative coloring approaches.

Color contrast ensures that important design elements remain visible and impactful. High contrast between text and background colors improves readability, while contrasting accent colors draw attention to key design features. The interplay between colored areas and natural metal finishes creates visual depth and sophistication.

Brand color accuracy maintains consistency with organizational identity standards. Our color matching capabilities ensure that corporate colors are reproduced accurately, maintaining brand integrity across all marketing materials and promotional items. Digital color proofing allows clients to verify color accuracy before full production begins.

Typography and Text Placement

Text placement on custom shaped challenge coins requires special attention to readability and visual hierarchy. Unlike round coins where text can follow circular patterns, custom shapes may require creative approaches to text placement that complement the overall design. Text should enhance rather than compete with other design elements.

Font selection impacts both readability and aesthetic appeal. Sans-serif fonts generally provide better readability at small sizes, while serif fonts may complement traditional or formal design themes. Custom lettering or organizational fonts help reinforce brand identity when appropriate.

Hierarchy establishment guides viewer attention through the design in intended sequences. Primary text elements such as organization names or event titles should receive prominent placement and sizing, while secondary information can be sized and positioned to support the primary message without overwhelming it.

Conclusion

Custom shaped challenge coins represent the perfect fusion of traditional values and modern manufacturing capabilities. At Badge Artisans Co., Ltd, we bring over a decade of experience, advanced zinc alloy die-cast technology, and unwavering commitment to quality to every project. Our comprehensive manufacturing capabilities, international certifications, and customer service excellence ensure that each custom challenge coin becomes a treasured symbol of achievement and belonging.

The evolution of custom shaped challenge coins from simple military recognition tokens to sophisticated commemorative pieces reflects their enduring power to create emotional connections and preserve meaningful memories. Whether recognizing military service, law enforcement dedication, corporate achievement, or educational excellence, these coins transcend their physical properties to become symbols of shared values and collective pride.

Our commitment to innovation drives continuous improvements in design capabilities, manufacturing processes, and customer service delivery. Investment in advanced technologies, sustainable practices, and skilled craftsmanship ensures that Badge Artisans Co., Ltd remains at the forefront of the custom challenge coin industry. We look forward to partnering with organizations worldwide to create custom shaped challenge coins that honor their unique stories and celebrate their achievements.

From concept to completion, every custom shaped challenge coin project receives the attention to detail and commitment to excellence that has established our reputation in the global marketplace. Contact Badge Artisans Co., Ltd today to begin creating your own custom shaped challenge coins that will serve as lasting symbols of recognition, achievement, and organizational pride for years to come.