Custom Diecast Medals – Premium Awards & Collectibles Premium custom diecast medals with zinc alloy construction, UV printing, and soft enamel. Expert manufacturing for track medals, martial arts awards & custom designs.

custom diecast medals (9)

The Art and Science of Custom Diecast Medals Manufacturing

In the competitive world of recognition and awards, custom diecast medals represent the pinnacle of craftsmanship, durability, and aesthetic appeal. These precision-engineered awards combine traditional metalworking techniques with cutting-edge manufacturing processes to create memorable keepsakes that celebrate achievements across diverse industries and applications.

The term “diecast” refers to a specific manufacturing process where molten metal is forced into precision-machined molds under high pressure, resulting in incredibly detailed and dimensionally accurate medals. This process enables the creation of complex three-dimensional designs that would be impossible to achieve through other manufacturing methods, making custom die cast medals the preferred choice for prestigious awards and commemorative pieces.

Modern custom diecast medals manufacturing has evolved far beyond simple gold, silver, and bronze finishes. Today’s advanced production techniques incorporate multiple materials, innovative coloring processes, and sophisticated design elements that transform medals from basic recognition tools into coveted collectibles and powerful branding instruments.

custom diecast medals (5)

Revolutionary Manufacturing Techniques in Modern Medal Production

Advanced Material Integration: Beyond Traditional Zinc Alloy

The foundation of exceptional custom diecast medals begins with material selection and innovation. While traditional zinc alloy remains the industry standard for its superior strength-to-weight ratio and detail reproduction capabilities, modern manufacturers are pioneering hybrid approaches that combine multiple materials for enhanced visual impact and functionality.

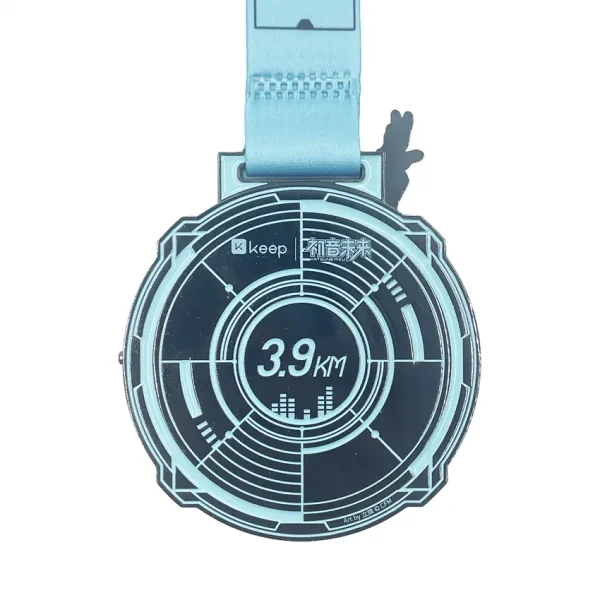

The Keep×Hatsune Miku collaboration medal exemplifies this innovative approach, combining zinc alloy construction with UV printing technology to create a multi-dimensional award that serves both as athletic recognition and collectible merchandise. This 76×94×11mm medal demonstrates how material innovation can support complex design requirements while maintaining structural integrity.

The zinc alloy foundation provides the necessary durability for long-term display and handling, while specialized surface treatments enable the application of vibrant, detailed graphics that remain crisp and fade-resistant over time. This dual-material approach represents a significant advancement in custom awards manufacturing, enabling creators to achieve previously impossible design complexity.

custom diecast medals (3) |

custom diecast medals (4) |

custom diecast medals (8) |

Precision Die Casting: Engineering Excellence in Every Detail

The die casting process for custom diecast medals requires extraordinary precision and technical expertise. Modern facilities utilize computer-controlled casting systems that maintain temperatures exceeding 1200°C while ensuring consistent material flow and dimensional accuracy across entire production runs.

The mold creation process represents a substantial investment in precision engineering. Custom molds for complex designs can cost upward of $8,000 per set, but this investment enables the production of medals with detail accuracy reaching 0.2mm tolerances. This level of precision allows manufacturers to reproduce intricate design elements, from delicate text to complex three-dimensional character representations.

Quality control throughout the die casting process involves multiple inspection points, ensuring that each medal meets exacting standards for dimensional accuracy, surface finish, and structural integrity. Advanced measuring equipment verifies that every production piece matches the original design specifications, maintaining consistency across quantities ranging from hundreds to thousands of pieces.

Revolutionary Surface Treatment Technologies

Modern custom printed medals benefit from advanced surface treatment technologies that dramatically expand design possibilities while ensuring long-term durability. UV printing technology has emerged as a game-changing innovation, enabling full-color graphics reproduction with exceptional detail and color accuracy.

The UV printing process creates a protective surface layer that passes rigorous durability testing, including 500-cycle abrasion resistance testing that ensures graphics remain vibrant despite regular handling and display. Color accuracy is maintained within ΔE≤2.0 tolerances, ensuring that final products accurately represent original artwork and branding elements.

Soft enamel techniques complement UV printing by providing tactile contrast and visual depth to medal designs. The combination of raised metal elements with recessed colored areas creates engaging visual and tactile experiences that enhance the perceived value and collector appeal of finished awards.

Design Innovation: Creating Medals That Transcend Traditional Boundaries

IP Collaboration: The New Frontier in Medal Design

The integration of intellectual property licensing into custom diecast medals manufacturing represents a revolutionary approach to award design that extends far beyond traditional sports and academic applications. The collaboration between fitness platform Keep and virtual idol Hatsune Miku demonstrates how modern medal design can bridge entertainment, fitness, and collector cultures.

This innovative approach requires manufacturers to navigate complex licensing requirements while maintaining the highest production standards. Badge Artisans Co., Ltd.’s experience with over 50 major IP collaborations, including Disney and Marvel partnerships, provides the expertise necessary to execute these complex projects while ensuring brand compliance and quality consistency.

The design process for IP collaboration medals involves close coordination between brand partners, rights holders, and manufacturing teams to ensure accurate representation of licensed characters while incorporating event-specific elements. The Keep×Hatsune Miku medal successfully integrates the character’s iconic design elements with fitness achievement recognition, creating a unique product that appeals to both anime enthusiasts and fitness participants.

Multi-Dimensional Design Elements

Advanced manufacturing capabilities enable the incorporation of complex three-dimensional design elements that create visually stunning and tactilely engaging custom awards. Laser engraving technology allows for precise character cutouts and layered design elements that create depth and visual interest impossible to achieve through traditional techniques.

The integration of gradient printing effects enables smooth color transitions that bring natural landscapes, character designs, and abstract concepts to life on medal surfaces. Multi-color printing processes allow for sophisticated color schemes that accurately reproduce complex artwork while maintaining production efficiency and cost-effectiveness.

Textural elements such as rope-pattern borders, raised relief areas, and contrasting finish treatments add visual and tactile interest that enhances the premium feel of finished medals. These design elements contribute to the overall perceived value and collector appeal of custom diecast medals.

Functional Design Integration

Modern medal design increasingly incorporates functional elements that extend utility beyond simple recognition. Custom bottle opener medals and belt buckle designs transform awards into practical items that recipients can use and display simultaneously, increasing long-term brand exposure and recipient satisfaction.

The integration of practical elements requires careful engineering to ensure that functional components do not compromise the medal’s primary recognition purpose while adding meaningful utility. This approach particularly appeals to corporate clients seeking awards that provide ongoing brand exposure through regular use.

Specialized Applications: Expanding the Custom Diecast Medal Market

Track Medals and Athletic Recognition

Track and field events represent one of the most demanding applications for custom diecast medals, requiring awards that can withstand outdoor conditions while maintaining visual appeal across diverse athletic achievements. The precision and durability of die cast construction make these medals ideal for multi-event competitions where consistent quality across different award categories is essential.

Custom track medals often incorporate sport-specific design elements such as running silhouettes, timing elements, and event-specific symbols that create immediate recognition and connection with participants. The ability to customize finishes in gold, silver, and bronze provides traditional recognition hierarchies while allowing for creative variations that reflect event themes or sponsor requirements.

The durability of custom die cast medals makes them particularly suitable for annual events where medal quality reflects directly on event prestige and participant satisfaction. Recipients often display these awards for decades, making long-term durability and fade resistance critical performance requirements.

Martial Arts Awards: Tradition Meets Innovation

Martial arts applications for custom diecast medals require designs that honor traditional values while incorporating modern manufacturing excellence. These awards often serve as rank advancement recognition, tournament achievements, or special accomplishment acknowledgments within martial arts communities.

The design process for martial arts medals frequently involves incorporating traditional symbols, cultural elements, and discipline-specific imagery that resonates with practitioners and instructors. The precision of die cast manufacturing enables accurate reproduction of complex traditional designs while allowing for personalization and event-specific customization.

Martial arts medals often require exceptional durability due to their significance in practitioner development and the likelihood of long-term retention and display. The inherent strength of zinc alloy construction combined with advanced surface treatments ensures these awards maintain their appearance and significance throughout recipients’ martial arts journeys.

Corporate Recognition and Employee Awards

The corporate recognition market represents a rapidly growing application area for custom diecast medals, particularly as companies seek meaningful ways to acknowledge employee achievements, milestone anniversaries, and performance excellence. These applications often require sophisticated design integration that seamlessly blends corporate branding with recognition messaging.

Corporate custom awards benefit from the premium perception associated with die cast construction, conveying the importance and value that organizations place on employee recognition. The ability to incorporate complex logos, detailed graphics, and multiple color elements makes these medals effective tools for reinforcing corporate culture and values.

The professional appearance and substantial feel of custom diecast medals make them appropriate for executive recognition, sales achievement awards, and special project acknowledgments where the award quality reflects the significance of the achievement being recognized.

Technical Excellence: Manufacturing Standards and Quality Assurance

Certification and Compliance Standards

Professional custom diecast medals manufacturing requires adherence to rigorous quality and safety standards that ensure consistent product excellence and regulatory compliance. Badge Artisans Co., Ltd.’s certifications including TÜVRheinland, Disney, BSCI, and Sedex demonstrate the comprehensive quality management systems necessary for producing awards that meet international standards.

These certifications encompass multiple aspects of manufacturing operations, including material sourcing, production processes, quality control procedures, and workplace safety standards. Disney certification specifically requires exceptional attention to detail and quality consistency, standards that benefit all custom medal production regardless of application.

The BSCI (Business Social Compliance Initiative) certification ensures that manufacturing operations meet ethical standards for worker welfare, environmental protection, and social responsibility. These standards are increasingly important for corporate clients seeking suppliers that align with their corporate social responsibility objectives.

Advanced Quality Control Protocols

Modern custom diecast medals production incorporates sophisticated quality control measures that monitor every aspect of the manufacturing process from raw material inspection through final packaging. Computer-controlled measuring systems verify dimensional accuracy, surface finish quality, and color consistency across production runs.

Statistical process control techniques identify potential quality variations before they impact production output, enabling real-time corrections that maintain consistent quality standards. These systems are particularly important for large-volume orders where maintaining consistency across thousands of pieces is critical for client satisfaction.

Final inspection procedures include comprehensive visual examination, dimensional verification, and functional testing for medals incorporating special features such as moving parts or integrated accessories. This multi-stage approach ensures that every medal meets or exceeds established quality standards.

Color Management and Consistency

Achieving consistent color reproduction across custom printed medals requires sophisticated color management systems that control every aspect of the printing and finishing process. Digital color matching systems ensure that printed colors accurately match approved artwork specifications while maintaining consistency across production batches.

The UV printing process enables precise color control with multiple ink layers that create depth and vibrancy impossible to achieve through traditional techniques. Color stability testing ensures that finished medals maintain their appearance through extended exposure to light, handling, and environmental conditions.

Regular calibration of printing equipment and color measurement systems ensures long-term consistency and enables accurate reproduction of complex corporate colors and brand specifications. This attention to color accuracy is particularly important for awards that will be displayed alongside other branded materials.

Market Dynamics: Understanding Custom Diecast Medal Applications

Emerging Market Segments

The custom diecast medals market continues to expand beyond traditional sports and academic applications into diverse new segments driven by changing recognition practices and cultural trends. Gaming tournaments, virtual fitness challenges, and social media competitions represent rapidly growing application areas that require innovative design approaches.

Corporate wellness programs increasingly utilize custom awards to recognize employee participation in health and fitness initiatives. These applications often require designs that balance professional appearance with motivational messaging, creating awards that recipients are proud to display in workplace environments.

Collector markets for limited-edition custom medals have emerged as entertainment properties and brands recognize the marketing potential of high-quality commemorative awards. These applications often justify premium pricing and sophisticated packaging that enhances the collector experience and perceived value.

Customization Trends and Client Expectations

Modern clients expect comprehensive customization options that extend far beyond basic color and text modifications. Advanced manufacturing capabilities enable custom shapes, integrated accessories, and multi-material construction that creates truly unique awards tailored to specific applications and brand requirements.

The demand for rapid prototype development and iterative design refinement requires manufacturing partners capable of producing high-quality samples quickly and cost-effectively. Digital design tools and rapid prototyping capabilities enable clients to visualize and refine designs before committing to full production.

Sustainability considerations increasingly influence material selection and manufacturing processes as clients seek environmentally responsible recognition solutions. Recycled materials, eco-friendly packaging, and local sourcing options address these concerns while maintaining quality and cost-effectiveness.

Innovation in Presentation and Packaging

Premium Packaging Solutions

The presentation of custom diecast medals plays a crucial role in recipient experience and perceived value. Professional packaging options range from basic protective poly bags to elaborate presentation boxes that enhance the award ceremony experience and long-term display options.

Custom packaging design often incorporates event branding, sponsor recognition, and thematic elements that extend the award experience beyond the medal itself. High-quality packaging materials and printing techniques create premium unboxing experiences that reflect the significance of the achievement being recognized.

Sustainable packaging solutions address environmental concerns while maintaining professional appearance and protective capabilities. Recyclable materials and minimalist design approaches reduce environmental impact without compromising presentation quality.

Digital Integration Possibilities

Emerging technologies enable the integration of digital elements that extend the medal experience beyond the physical award. QR codes can link to digital certificates, photo galleries, or social media integration that enhances the recognition experience and provides ongoing engagement opportunities.

Near-field communication (NFC) technology embedded in medals can trigger smartphone applications that display achievement details, event information, or personalized messages from award sponsors. These technologies create interactive experiences that bridge physical and digital recognition methods.

Blockchain verification systems provide authentication capabilities that prevent counterfeiting while creating permanent achievement records. These systems are particularly valuable for high-value awards or limited-edition collectibles where authenticity verification is important.

Economic Considerations: Investment and Value Optimization

Cost Structure Analysis

Understanding the cost structure of custom diecast medals production enables informed decision-making that balances quality requirements with budget constraints. Initial tooling costs represent significant investments that are amortized across production quantities, making volume planning crucial for cost optimization.

Material costs vary based on alloy specifications, finishing requirements, and special features integration. Premium materials and sophisticated finishing techniques increase per-unit costs but may be justified by enhanced perceived value and long-term durability requirements.

Labor costs encompass skilled craftsmanship for complex design elements, quality control procedures, and specialized packaging requirements. Efficient production planning and automation integration help control labor costs while maintaining quality standards.

Value Engineering Approaches

Effective value engineering balances cost optimization with quality maintenance through strategic design and manufacturing decisions. Standardized components, efficient production sequences, and material optimization reduce costs without compromising award quality or visual impact.

Modular design approaches enable cost-effective customization by utilizing common base components with variable design elements. This strategy reduces tooling costs while enabling significant visual customization through surface treatments and accessory integration.

Volume planning optimization considers production efficiency, inventory management, and delivery scheduling to minimize overall project costs. Strategic ordering timing can take advantage of production capacity optimization and material purchasing efficiencies.

Future Trends: The Evolution of Custom Diecast Medal Manufacturing

Technology Integration and Smart Manufacturing

Industry 4.0 technologies are revolutionizing custom diecast medals manufacturing through automation, data analytics, and predictive quality control systems. Smart manufacturing systems optimize production efficiency while maintaining the high quality standards essential for premium recognition products.

Artificial intelligence applications in design optimization help create medals that maximize visual impact while minimizing production complexity and costs. These systems can suggest design modifications that improve manufacturability without compromising aesthetic objectives.

Robotics integration in finishing processes ensures consistent quality while reducing labor costs and production timelines. Automated systems excel at repetitive precision tasks while human expertise focuses on design, quality assurance, and client relationship management.

Sustainability and Environmental Responsibility

Sustainable manufacturing practices are becoming essential competitive advantages as clients increasingly prioritize environmental responsibility. Recycled materials, energy-efficient production processes, and waste reduction initiatives address environmental concerns while maintaining quality standards.

Life cycle assessment approaches evaluate the environmental impact of custom medals from raw material sourcing through end-of-life disposal. This comprehensive analysis identifies opportunities for environmental impact reduction throughout the product lifecycle.

Carbon footprint reduction through local sourcing, efficient logistics, and renewable energy utilization addresses climate change concerns while potentially reducing production costs. These initiatives often align with corporate sustainability objectives and procurement requirements.

Conclusion: Excellence in Custom Diecast Medal Manufacturing

Custom diecast medals represent the convergence of traditional craftsmanship, advanced manufacturing technology, and innovative design thinking. The evolution from simple recognition tokens to sophisticated branding tools and collectible awards reflects the growing importance of meaningful recognition in diverse applications from athletic achievement to corporate excellence.

The technical excellence required for producing premium custom die cast medals demands expertise in metallurgy, precision manufacturing, surface treatment technologies, and quality assurance systems. Manufacturers like Badge Artisans Co., Ltd. combine these technical capabilities with creative design expertise and comprehensive client support to deliver awards that exceed expectations while meeting demanding timeline and budget requirements.

Whether recognizing athletic achievement through track medals, honoring martial arts progression, celebrating corporate milestones, or creating collectible commemoratives, custom diecast medals provide tangible recognition that creates lasting memories and meaningful connections between achievements and recognition.

The future of custom diecast medals manufacturing will continue to evolve through technology integration, sustainability initiatives, and expanding application markets. However, the fundamental human desire for meaningful recognition through beautiful, durable awards ensures that expertly crafted custom medals will remain essential tools for celebrating achievement across all aspects of human endeavor.

For organizations seeking to recognize achievements, build brand awareness, or create memorable experiences, custom diecast medals offer unparalleled opportunities to create lasting impressions that honor accomplishments while reflecting the values and quality standards of the recognizing organization. The investment in premium custom awards pays dividends through enhanced recipient satisfaction, brand recognition, and long-term relationship building that extends far beyond the initial award ceremony.

Please contact experienced manufacturers to discuss your custom diecast medal requirements and discover how these exceptional awards can enhance your recognition programs while creating lasting value for recipients and organizations alike.