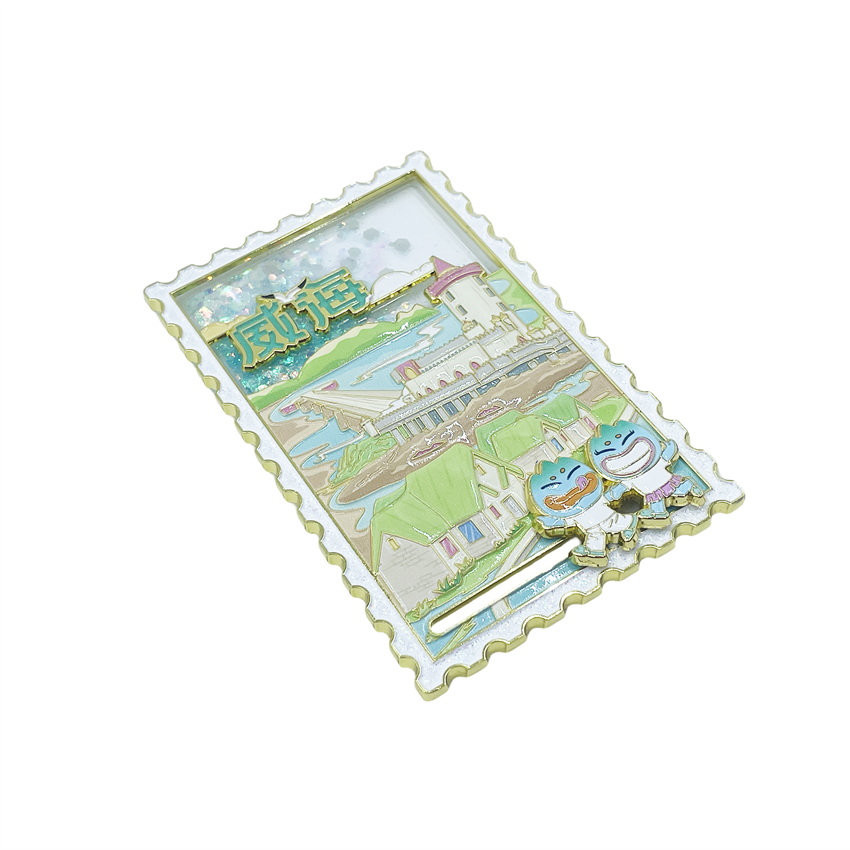

The humble refrigerator has evolved far beyond its primary function as a food storage appliance. Today’s modern kitchen centers around the fridge as a family communication hub, memory keeper, and personal gallery space. Custom magnets fridge solutions have revolutionized how we interact with this essential appliance, transforming cold metal surfaces into warm, personalized displays that tell our unique stories.

custom magnets fridge (1)

The Evolution of Refrigerator Magnets: From Simple Tools to Cultural Artifacts

Refrigerator magnets have transcended their origins as simple functional items. What began as basic promotional tools for businesses has blossomed into a sophisticated industry of personalized magnets that serve multiple purposes. Modern fridge magnets combine artistic expression with practical functionality, creating magnetic signs that capture memories, promote businesses, and add personality to kitchen spaces.

The magnetic material technology behind today’s custom fridge magnets represents decades of innovation. High-quality zinc alloy construction ensures durability, while advanced UV printing techniques deliver vibrant, fade-resistant colors that maintain their brilliance for years. This evolution has enabled the creation of shaped magnet designs that were impossible with earlier manufacturing methods.

custom magnets fridge (2) |

custom magnets fridge (3) |

Understanding Premium Magnetic Material: The Foundation of Quality

The choice of magnetic material fundamentally determines the performance and longevity of custom magnets fridge applications. Professional-grade refrigerator magnets utilize zinc alloy as the base material, providing superior strength-to-weight ratios compared to traditional alternatives. This premium magnetic material offers several distinct advantages:

Zinc alloy construction delivers exceptional durability while maintaining optimal magnetic field strength. The material resists corrosion, ensuring that your personalized magnets maintain their appearance and functionality even in high-humidity kitchen environments. Additionally, the smooth surface texture of zinc alloy provides an ideal foundation for UV printing, enabling intricate designs and vibrant color reproduction.

The thickness specification of 3mm represents the optimal balance between magnetic strength and practical application. This dimension ensures reliable adhesion to various metal surfaces while preventing excessive bulk that might interfere with refrigerator door seals or create uneven surfaces when multiple magnets are positioned together.

UV Printing Technology: Bringing Designs to Life

Modern custom fridge manufacturing relies heavily on UV printing technology to achieve professional-grade results. This advanced printing method offers significant advantages over traditional screen printing or digital printing alternatives. UV printing creates a direct bond between the ink and the magnetic material, resulting in exceptional durability and color vibrancy.

The UV printing process begins with specialized inks that contain photoinitiators. When exposed to ultraviolet light, these inks cure instantly, creating a permanent bond with the zinc alloy surface. This immediate curing process prevents ink bleeding and enables precise reproduction of fine details, making it ideal for complex designs that incorporate multiple cultural elements or intricate photographic imagery.

Temperature resistance represents another crucial advantage of UV printing for fridge magnets. Kitchen environments subject magnetic signs to temperature fluctuations from cooking activities and appliance heat generation. UV-cured inks maintain their color stability and adhesion integrity across a wide temperature range, ensuring long-term performance in demanding kitchen conditions.

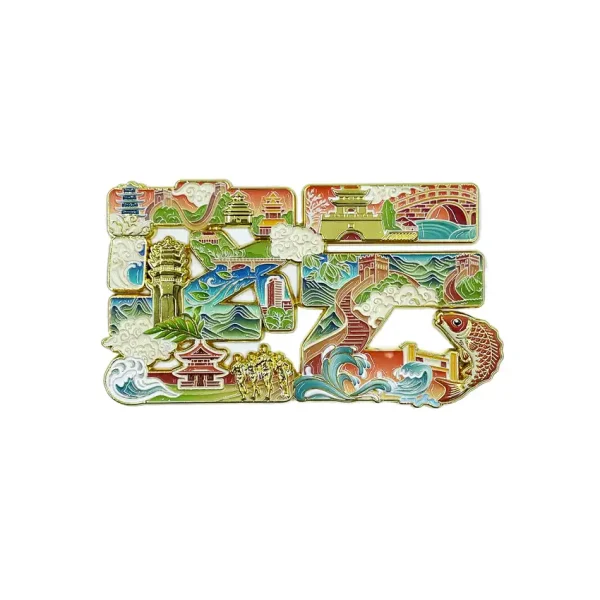

Design Philosophy: Cultural Storytelling Through Magnetic Art

The most compelling custom magnets fridge designs transcend simple decoration to become cultural storytelling devices. Professional design approaches recognize that refrigerator magnets serve as daily touchpoints with personal memories and cultural connections. This understanding drives the creation of designs that combine aesthetic appeal with meaningful symbolism.

Cultural theme integration represents a sophisticated approach to personalized magnets design. By incorporating recognizable cultural symbols, architectural elements, and traditional motifs, designers create magnetic collections that serve as miniature cultural ambassadors. These designs enable individuals to display their heritage, travel experiences, or cultural interests in an accessible, everyday format.

The layered symbolism approach ensures that custom fridge magnets reward both casual viewing and detailed examination. Surface-level visual appeal draws initial attention, while deeper symbolic elements provide ongoing discovery opportunities. This multi-layered design philosophy transforms simple magnetic material into conversation starters and memory triggers.

Manufacturing Excellence: From Concept to Completion

Professional custom magnets fridge production requires sophisticated manufacturing capabilities that integrate multiple specialized processes. The production workflow begins with computer-aided mold designing, utilizing advanced 3D modeling software to create precise tooling specifications. This digital design phase ensures that complex shaped magnet profiles can be manufactured with consistent quality and dimensional accuracy.

Die casting represents the critical forming process for zinc alloy magnetic components. This manufacturing method involves injecting molten zinc alloy into precision-machined molds under high pressure. The result is dimensionally accurate components with smooth surface finishes that provide optimal foundations for subsequent UV printing operations.

Quality control measures throughout the manufacturing process ensure that each custom fridge magnet meets stringent performance standards. Magnetic strength testing verifies adequate holding power, while surface preparation inspections ensure optimal UV printing adhesion. Color matching protocols guarantee that finished products accurately reproduce approved design specifications.

Applications Beyond Traditional Fridge Magnets

While refrigerator magnets remain the primary application, modern magnetic material technology enables diverse uses across multiple environments. Custom magnets fridge solutions extend to office environments, where magnetic signs serve as organizational tools on filing cabinets and metal office furniture. Educational institutions utilize personalized magnets for classroom displays and student recognition programs.

Promotional applications represent a growing market segment for custom fridge magnets. Businesses recognize the value of magnetic marketing materials that provide ongoing brand exposure in high-traffic household locations. Unlike disposable promotional items, quality magnetic signs remain visible for extended periods, delivering sustained marketing impact.

The rise of magnetic calendars demonstrates the functional versatility of modern fridge magnets. These applications combine practical scheduling capabilities with personalized design elements, creating useful household tools that complement kitchen aesthetics while serving essential organizational functions.

Photo Magnets: Preserving Memories in Magnetic Form

Photo magnets represent one of the most popular personalized magnets categories, enabling individuals to display treasured memories in convenient, accessible formats. Modern UV printing technology reproduces photographic imagery with exceptional fidelity, capturing subtle color gradations and fine details that preserve the emotional impact of original photographs.

The process of creating photo magnets begins with digital image optimization to ensure optimal reproduction quality. Professional preparation includes color correction, resolution enhancement, and composition adjustments that maximize the visual impact within the constraints of the magnetic format. This careful preparation ensures that finished photo magnets capture the essence of original images while adapting to the unique characteristics of the magnetic medium.

Durability considerations for photo magnets require specialized attention to UV printing parameters and surface preparation techniques. Photographic imagery often contains subtle tonal variations that demand precise ink deposition and curing protocols. Professional manufacturers utilize calibrated UV printing systems that deliver consistent results across varying image types and complexity levels.

Die Cut Magnets: Custom Shapes for Unique Expression

Die cut magnet technology enables the creation of custom shapes that extend far beyond traditional rectangular formats. This manufacturing capability opens creative possibilities for shaped magnet designs that reflect specific themes, logos, or artistic concepts. The die cutting process utilizes precision tooling to create clean, accurate edge profiles that enhance the professional appearance of finished magnets.

Complex die cut shapes require careful consideration of magnetic material properties and structural integrity. The zinc alloy construction of premium magnetic material provides sufficient strength to support intricate cut patterns without compromising magnetic performance. However, design optimization ensures that narrow sections and delicate features maintain adequate thickness for reliable long-term use.

The relationship between die cut shapes and magnetic field distribution requires technical expertise to achieve optimal performance. Professional design services consider magnetic flux patterns when developing custom shapes, ensuring that irregular geometries maintain effective holding power across the entire magnet surface.

Professional Design Services: Bringing Visions to Reality

Many manufacturers of custom magnets fridge solutions offer comprehensive design services that transform client concepts into finished products. These services typically include consultation, concept development, design refinement, and production preparation phases that ensure successful project outcomes.

The design consultation process begins with understanding client objectives, target applications, and aesthetic preferences. Professional designers utilize this information to develop initial concepts that balance creative vision with manufacturing constraints and performance requirements. This collaborative approach ensures that finished designs meet both functional and aesthetic objectives.

Frequently asked questions during the design phase often focus on size limitations, color reproduction capabilities, and timeline requirements. Professional design services address these concerns through clear communication and realistic expectation setting, ensuring that clients understand both the possibilities and limitations of the magnetic medium.

International Quality Standards and Certifications

Professional manufacturers of personalized magnets operate under strict quality management systems that ensure consistent product quality and regulatory compliance. International certifications such as TÜV Rheinland, BSCI, and Sedex demonstrate commitment to quality, safety, and ethical manufacturing practices.

These certifications require ongoing auditing and compliance verification across multiple operational areas. Manufacturing processes, material sourcing, worker safety protocols, and environmental management systems all undergo regular evaluation to maintain certification status. This comprehensive approach to quality management provides confidence in the reliability and safety of finished magnetic products.

Environmental considerations represent an increasingly important aspect of magnetic material production. Certified manufacturers implement sustainable practices that minimize environmental impact while maintaining product quality. These efforts include recycling programs for production waste, energy-efficient manufacturing processes, and responsible sourcing of raw materials.

Market Trends and Future Developments

The custom magnets fridge market continues to evolve in response to changing consumer preferences and technological advances. Digital printing technology improvements enable more complex designs with enhanced color reproduction and faster production times. These developments reduce costs and lead times while expanding creative possibilities for magnetic applications.

Smart home integration represents an emerging trend that may influence future magnetic product development. As kitchen appliances become increasingly connected and interactive, magnetic accessories may evolve to incorporate electronic components or interactive features that complement smart home ecosystems.

Sustainability considerations drive innovation in magnetic material formulations and manufacturing processes. Research into alternative materials and recycling technologies aims to reduce environmental impact while maintaining the performance characteristics that make magnetic products attractive to consumers.

Shipping Method Considerations for Magnetic Products

The magnetic properties of custom fridge magnets create unique considerations for packaging and shipping. Professional manufacturers utilize specialized packaging methods that prevent magnetic interference while protecting products during transit. These techniques include magnetic field isolation, cushioned packaging, and careful orientation control to minimize handling issues.

International shipping of magnetic products requires compliance with various transportation regulations that govern magnetic materials. Professional logistics services understand these requirements and implement appropriate documentation and packaging protocols to ensure reliable delivery while meeting regulatory obligations.

Order fulfillment systems for magnetic products must account for the unique handling requirements of magnetic materials. Automated sorting and packaging systems require specialized equipment that can safely process magnetic products without interference with electronic systems or other magnetic items.

Conclusion: The Enduring Appeal of Custom Magnets Fridge

Custom magnets fridge solutions represent a unique intersection of functionality, artistry, and personal expression. Through advanced manufacturing techniques, premium magnetic materials, and professional design services, these products transform everyday household items into meaningful expressions of identity and memory.

The evolution of magnetic technology continues to expand creative possibilities while maintaining the fundamental appeal that has made refrigerator magnets a household staple for decades. As manufacturing capabilities advance and design sophistication increases, custom magnets fridge applications will undoubtedly continue to find new ways to enhance our daily lives and preserve our most treasured memories.

Whether serving as promotional tools, artistic expressions, or memory keepers, high-quality custom fridge magnets demonstrate the power of thoughtful design and precision manufacturing to create products that transcend their utilitarian origins to become cherished personal artifacts that brighten kitchens and hearts alike.