When preparing for an event, conducting a pilot run, or simply needing a handful of commemorative items, many people immediately search for custom medals no minimum order services. This type of service sounds highly flexible and appealing. However, as a direct factory specializing in medal manufacturing, we must be honest: “No Minimum Order” often translates to a much higher unit cost and severely limited quality.

This article will pull back the curtain on how “no minimum order” models actually work. Our goal is to equip you with the knowledge to avoid pricing pitfalls and make the most informed, economical decision for your organization’s medal procurement.

Why Does “No Minimum” Sound Good But Cost a Fortune?

If you find a vendor claiming “no minimum order,” they typically operate under one of these two models:

Model One: The High-Price Strategy of Retailers or Traders

Medals-in-Different-Colors

These businesses usually lack their own production lines. They rely on a system of “buying generic blank medals” + “simple post-production processing.” They purchase bulk quantities of commonmedal bases (such as plain metal or plastic name tags) and then fulfill your order by performing basic steps like laser engraving, applying stickers, or digital printing.

Because they function as retailers, they must factor in inventory, warehousing, and significant retail profit margins. Therefore:

-

The Unit Price is Exorbitantly High: A large portion of what you pay covers the retailer’s profit, not the actual production cost.

-

Quality is Restricted: You are prevented from utilizing professional craftsmanship like stamping, enamel, or die-casting, resulting in a finished product that often lacks the detail and premium feel required for corporate branding.

Model Two: The Simple Craftsmanship of Small Workshops

blank-medals-vs-customized-medals

The other category includes smaller operations that utilize low-threshold, basic equipment. They can only produce extremely simple medals, such as common button medals with a printed film overlay. While they can satisfy the demand for custom medals no minimum order due to simple production, their durability and refinement usually fall short of a company’s professional standards for brand image.

The Direct Factory Cost Structure: The Craftsmanship Behind Our Minimum Order

We enforce a minimum order quantity (MOQ), typically starting at 100 units, not to create a hurdle, but to ensure you receive the highest quality product at the most cost-effective price. This policy is directly tied to the fixed costs of professional medal manufacturing:

1. Tooling/Mould Fee: The Unavoidable “Startup” Cost

high-precision molds-engrave-making

For high-quality metal medal using premium processes like die-casting, enamel, or hard enamel, the first crucial step is creating a custom mould specifically for your design. This cost is one-time and fixed. Whether you produce 1 piece or 1,000 pieces, the initial mould cost must be incurred.

2. Machine Setup and Color Matching

Professional manufacturing equipment requires significant time and labor for initial setup, calibration, material preparation, and precise color matching to meet Pantone or corporate standards. These labor and machine hours are considered fixed costs, regardless of the number of items being produced.

The Conclusion: If you only produce 1–10 units, all these fixed costs are absorbed by those few pieces, driving the unit price to an unsustainable level. By spreading these costs across 100 or more units, the price per medal drops dramatically. For any company focused on both value and quality, bulk customization is the only truly viable option.

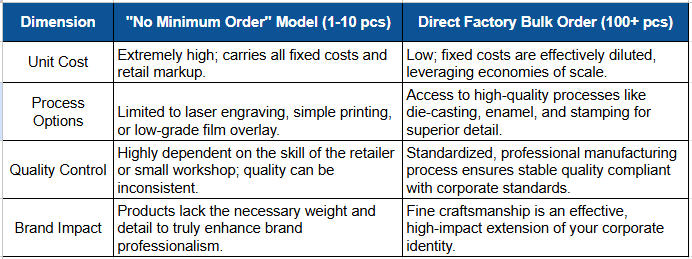

The Core Value Comparison: Cost Efficiency vs. Quality Assurance

The Core Value Comparison Cost Efficiency vs. Quality Assurance

Our analysis shows that the unit cost for ordering 100 custom medals can be 50% to 80% lower than the unit cost charged by a vendor offering custom medals no minimum order for just 5–10 pieces.

Procurement Advice: How to Maximize the Cost-Effectiveness of Your Medal Purchase

If you are a procurement manager, we offer two essential recommendations to help you balance budget and requirements:

1. Plan for Long-Term Inventory

Instead of frequently searching for “no minimum order” services, view your medals as long-term assets or brand inventory. By ordering 100 units or more in a single batch, you avoid recurring mould fees, design fees, and multiple shipping costs. This holistic approach proves to be the most budget-friendly over time.

2. Utilize Professional Sampling Services

We understand the need to verify the final quality before committing to a large order. You can utilize our sampling service by paying a small fee to produce 1–5 samples. Crucially, if you are satisfied and proceed with a bulk order of 100 units or more, we will fully refund or credit the sampling fee back to your final invoice.

This approach successfully converts your small-batch need into a “quality confirmation before bulk order,” ensuring you can personally inspect the quality while still benefiting from the best possible factory pricing.