Military Challenge Coin Design Secrets: Mastering 3D Relief and Enamel for Maximum Impact

Part I: Introduction – Defining the Design Imperative

A successful challenge coin design transcends simple graphics; it is a critical piece of metal engineering that tells a powerful story. For high-stakes projects, mastering the interplay of material, dimension, and color is essential to ensure a product that stands the test of time and meets professional standards. Our goal is to transform your initial concept into a powerful, high-impact reality, starting with the foundation of your military coin design.

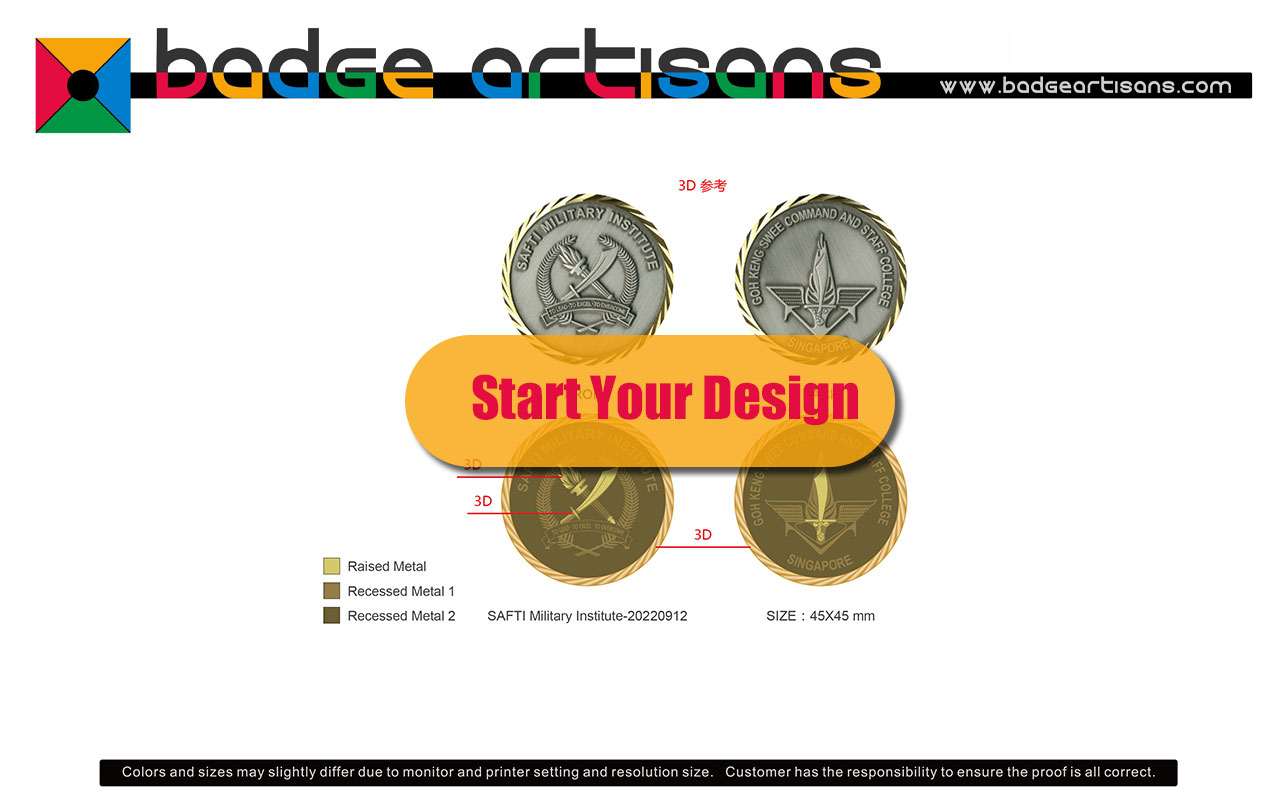

Comparison-between-the-physical-product-and-the-design-drawing

This definitive guide serves as your technical reference, revealing manufacturing secrets for utilizing 3D Relief and advanced Enamel techniques. We will show you how to elevate your final custom challenge coins to the highest level of craftsmanship.

Part II: The Art of Relief: 2D, 3D, and Multi-Level Design

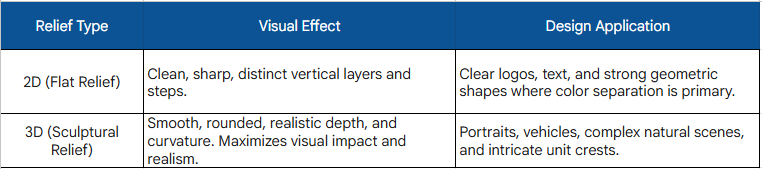

The choice of relief is the single most critical decision impacting the final feel and visual depth of your custom metal coin.

2.1 Dimensional Impact: 2D vs. 3D Relief

Dimensional Impact 2D vs. 3D Relief

2.2 The Secret to Depth: Multi-Level Structure

Custom Toms River Police Badges -2

High-end challenge coin design utilizes a Multi-Level structure (Raised Metal, 2nd Level, Recessed Metal). Our factory specializes in the Zinc Alloy Die Casting process. This technique offers excellent material fluidity, making it superior for achieving the complex, multi-level 3D Relief and intricate inner cutouts often demanded by top-tier military coin design projects.

2.3 Technical Design Constraints

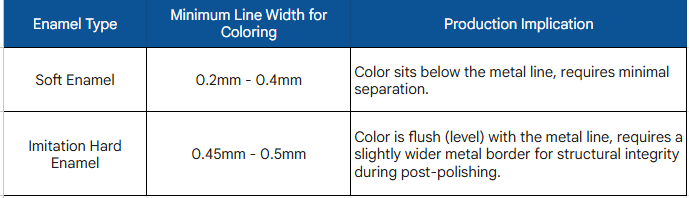

All submitted artwork must be Vector Artwork and must strictly adhere to the following technical line width parameters to ensure accurate filling of Pantone Colors.

Technical Design Constraints

Part III: The Enamel Choice: Soft vs. Imitation Hard Enamel

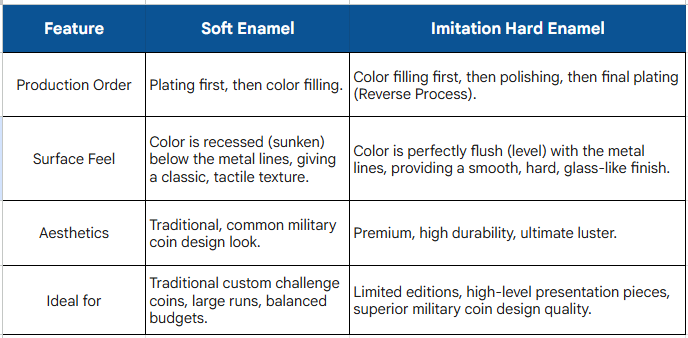

The enamel type fundamentally dictates the coin’s durability, texture, and perceived value—a critical consideration for any challenge coin design.

The Enamel Choice Soft vs. Imitation Hard Enamel

Part IV: Surface Treatments: Luster, Contrast, and Texture

The metal finish is essential for amplifying the visual impact and perceived quality of your command coin design.

4.1 Plating Philosophy: Antique vs. Shiny

Plating-Philosophy-Antique-vs.-Shiny

-

Antique Plating: Finishes such as Antique Gold or Antique Silver are ideal for detailed 3D coins. The dark oxidation retained in the recessed areas dramatically enhances relief depth and detail, lending a rich, historical appearance to the military coin design.

-

Shiny Plating: Finishes like Shiny Gold, Nickel, or Black Nickel provide high contrast and a modern, striking look, often used when design clarity is paramount.

4.2 The Contrast Secret: Textures and Dual Tones

To maximize contrast, the recessed background areas can be treated to create a matte texture. This is achieved using techniques like Sandblasting or Spark Erosion in the mold, which creates a precise, granular background that makes the highly polished raised metal elements “pop.” We also offer Dual-Tone Plating, combining two distinct finishes (e.g., shiny raised metal and antique recessed areas) to further define the complex design elements of your challenge coin design.

Part V: Advanced Design Effects

To create truly unique custom challenge coins, consider these specialized techniques:

Metal Military Coins Antique Silver and Shiny Gold

-

UV Printing: Excellent for designs requiring complex gradients, photographic elements, or logos with too many colors for traditional enamel. Our capability supports printing directly onto both flat and 3D curved surfaces.

-

Special Enamels: We can incorporate Luminous Color (glow-in-the-dark) or Glitter (sparkle) effects, which are combined with Soft Enamel for unique visual flair.

-

Hollow-Outs and Translucent Effects: Utilizing the precision of Zinc Alloy Die Casting, we can achieve complex hollow-out designs or fill areas with Transparent Glass Enamel, creating a luxurious, jewel-like effect.

Part VI: Conclusion and Next Steps

The successful execution of any challenge coin design hinges on an intimate knowledge of manufacturing capabilities. By consciously planning for the potential of 3D/Multi-Level Relief, selecting the perfect Enamel for your quality standard, and utilizing Plating Contrast, you guarantee a final product with maximum visual and symbolic impact.

Leverage our 15 years of expertise in Zinc Alloy Die Casting and precision finishing. We are your dedicated factory partner in realizing a superior military coin design project.

Initiate Your Design Now: Contact our project specialists today to submit your concept and receive a FREE, professional design consultation and factory quotation within 24 hours.