The Definitive Guide to Command Coins Custom: A 7-Step Process from Concept to Secure Delivery

Introduction: Setting the Standard for Command Coin Customization

For organizations and procurement units, acquiring high-quality command coins custom manufactured is critical. These items are tangible symbols of honor, mission success, and unit identity. Sourcing these bespoke items demands three things: uncompromised quality, strict security protocols, and dependable lead times.

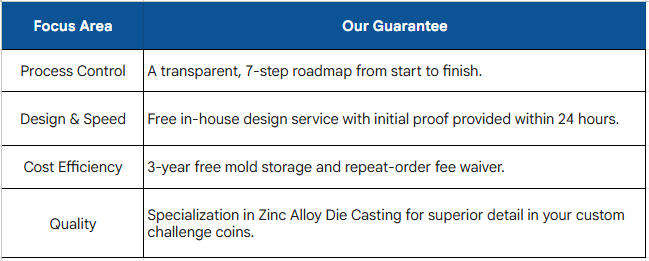

Sourcing often involves confusing processes, leading to hidden costs or quality inconsistencies. Backed by 15 years of dedicated manufacturing expertise, we provide a transparent, professional 7-Step Custom Command Coin Process managed end-to-end by our project specialists. This ensures your high-stakes project is executed flawlessly, on time, and to military-grade specifications.

Key Takeaways from This Guide

our core strength

Section II: Step-by-Step Customization – Your Professional Project Plan

We approach every order for command coins custom manufacturing with operational precision. Here is the detailed, transparent process managed by your dedicated project specialist.

Step 1: Project Scoping and Requirement Confirmation

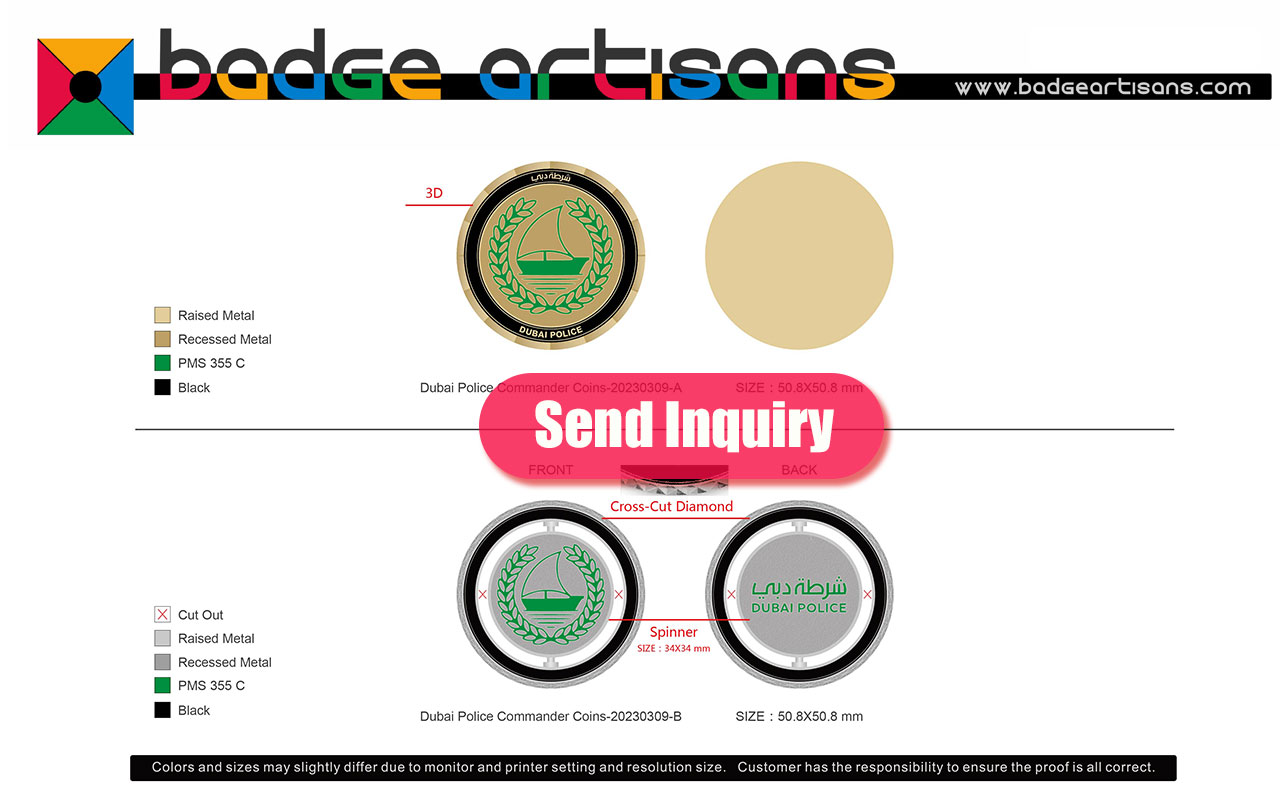

Commander Fighter Wing Epoxy Challenge Coins

The goal is to establish a solid foundation before design begins. We finalize all critical details: required quantity (our MOQ starts at 100pcs), dimensional specifications, target budget, and the necessary delivery schedule.

Security First: For sensitive projects involving unit insignias, we immediately formalize a Non-Disclosure Agreement (NDA) to protect your intellectual property. All color references for your custom challenge coins are defined using the globally recognized Pantone Color Reference System.

Step 2: Free In-House Design & Rapid Artwork Proof

Leveraging our 15 years in the production industry, our internal design team designs for optimal manufacturability. Our designers possess rich experience, ensuring your artwork is ready for the die-casting process.

The Factory Advantage: We provide a complimentary, all-inclusive design service. Our factory designers can deliver your initial, high-resolution design proof within 24 hours. Furthermore, we offer personalized presentation packaging design services to ensure a cohesive final product, perfect for any unit receiving these custom challenge coins.

Step 3: Materials, Die Casting, and Mold Protection

high-precision molds-engrave-making

We specialize in the Zinc Alloy Die Casting process. Known for its excellent fluidity and cost-effectiveness, zinc alloy is ideal for producing complex shapes, multi-level 3D relief, and intricate cutouts, commonly required for high-detail command coins custom orders. For subtle surface texture, the mold may incorporate Spark Erosion to achieve a fine sandblasted effect.

Unmatched Cost Efficiency: We offer a significant long-term saving: we will store your mold tooling for three years at no charge. Any repeat orders for the same design placed within this period receive a complimentary mold fee waiver.

Step 4: Sampling and Client Veto Power

Following precision mold creation and heat treatment, a physical sample (the “first strike”) is produced.

Critical Quality Check: We provide you with high-definition physical proofs (photos/video). This is your final quality checkpoint. You must confirm the coin’s weight, tactile feel, 3D relief depth, and Pantone color accuracy before we proceed to mass production. Your approval guarantees consistency across the entire order of custom military coins.

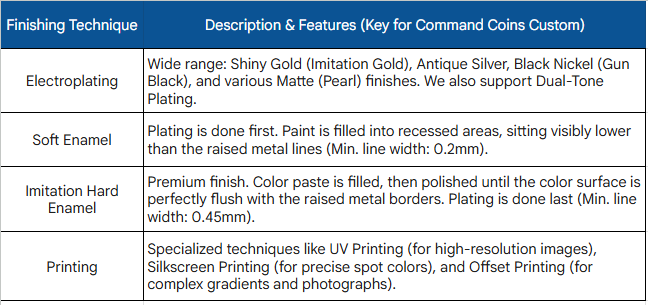

Step 5: Mass Production & Mastering Surface Treatments

Once approved, high-volume production begins, utilizing the expertise of our production team for precision finishing.

Mass Production & Mastering Surface Treatments

surface-process-techonlogy-of-challenge-coins-sample

Step 6: Multi-Stage Quality Control and Packaging

packing &QC

Quality is non-negotiable. Every finished coin undergoes rigorous In-Process QC and a final Out-Going QC inspection before packing to eliminate defects.

Packaging Solutions: The professional default packaging is the protective OPP Clear Bag. For presentation, we offer premium options including Velvet Pouches, Hard Gift Boxes (Top & Bottom Style), and Clear Acrylic Presentation Boxes, ideal for custom military coins.

custom-challenge-coin-packing-Velvet-box-

Step 7: Secure Logistics and Final Delivery

factory-06

The completed order is prepared for global delivery. We utilize trusted international freight carriers, ensuring secure and fully trackable shipping to your designated location. All shipments include a final QC Report and detailed Packing List, ensuring confidence in your order fulfillment.

Section III: Your Factory Advantage – Why Partner with Us?

Our facility is structured to mitigate the risks B2B buyers often face, ensuring a superior purchasing experience for command coins custom projects.

-

15 Years of Proven Expertise: Our track record ensures we meet the stringent quality standards required for official commemorative items.

-

Risk-Free & Rapid Design: Our internal free design team significantly reduces your upfront development costs and delivers professional concept proofs in just 24 hours.

-

Cost Efficiency Leader: Our 3-year mold retention and waiver policy provides guaranteed long-term savings for recurring orders of custom challenge coins.

-

Technical Specialization: Our focus on Zinc Alloy Die Casting allows us to affordably produce intricate, high-detail, multi-level command coins custom.

Conclusion: Ready to Initiate Your Custom Command Coin Mission?

Choose a partner that guarantees a smooth, high-quality, and secure experience. Our transparent, expert-backed 7-step process is ready for your next Command Coins Custom project.

Initiate Your Project Now: Contact our project specialists today to discuss your design concept and receive your FREE, competitive factory quotation within 24 hours.