When sourcing custom ID badges for employees, procurement professionals often struggle with one common issue: vendor quotes are often opaque, riddled with hidden fees, and highly inconsistent. It’s hard to tell if you’re getting true value.

As a direct factory specializing in high-quality zinc alloy, metal, and acrylic badges, we believe that price transparency is the foundation of a successful long-term partnership. This article will provide a detailed, clear breakdown of ID badge costs, helping you understand where your money goes so you can ensure you receive professional-grade identification that matches your company’s image—all while staying within budget.

I. Deconstructing the Core Cost: What Makes Up Our Direct Factory Price?

Your badge order total is derived from two main components: Fixed Costs, which you pay only once, and Variable Costs, which fluctuate with the quantity you order.

1. Fixed Costs: The Foundation of Scale Customization

These costs are necessary investments to begin production and are paid only once, regardless of whether you order 100 or 1,000 badges. Because we are a direct manufacturer, our fixed costs are generally lower and more transparent than those from a trading company.

mould-engraving

-

Mould/Tooling Fee: This is required only for non-standard shapes, particularly with metal badges like zinc alloy. This one-time fee ensures the final badge detail and precision. Once the mould is made, you can use it for all future reorders.

-

Design/Setup Fee: The initial cost of converting your logo and design files into production-ready formats (e.g., preparing the mold layout, color matching, and machine calibration). Our advantage here: We often offer free design services, significantly lowering your upfront investment.

2. Variable Costs: The True Unit Price Drivers

These costs increase proportionally with the number of badges you order. The larger the quantity, the more efficiently these costs are applied to each unit.

-

Raw Material Cost: The actual cost of zinc alloy, acrylic sheets, enamel/paint pigments, UV printing materials, and protective coatings.

-

Processing & Labor: The cost of machine time and skilled labor for die-casting (for zinc alloy), polishing, sanding, coloring (enamel or hard enamel), or UV printing, quality control, and packaging.

-

Accessory Cost: The price of the back attachments—such as magnetic clips, pins, or clutch fasteners—and their installation.

II. The 5 Factors That Dictate Your Final Unit Price

Beyond the basic cost structure, these five factors significantly influence whether your custom ID badges for employees order falls on the low or high end of the pricing spectrum:

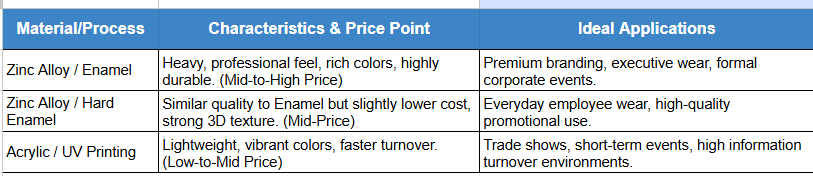

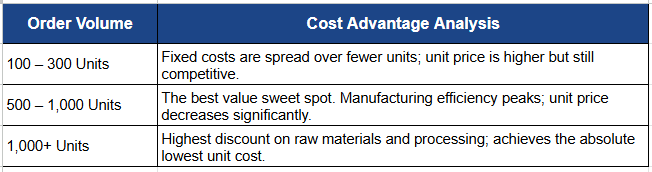

Factor 1: Core Material and Craftsmanship (Our Key Expertise)

The material and process are the primary drivers of badge price and overall quality

Factor 2: Order Quantity and Economies of Scale

Order Quantity and Economies of Scale

Quantity is the most critical variable affecting the unit price. As a direct factory, we maximize efficiency with bulk orders, which translates to superior pricing for you.

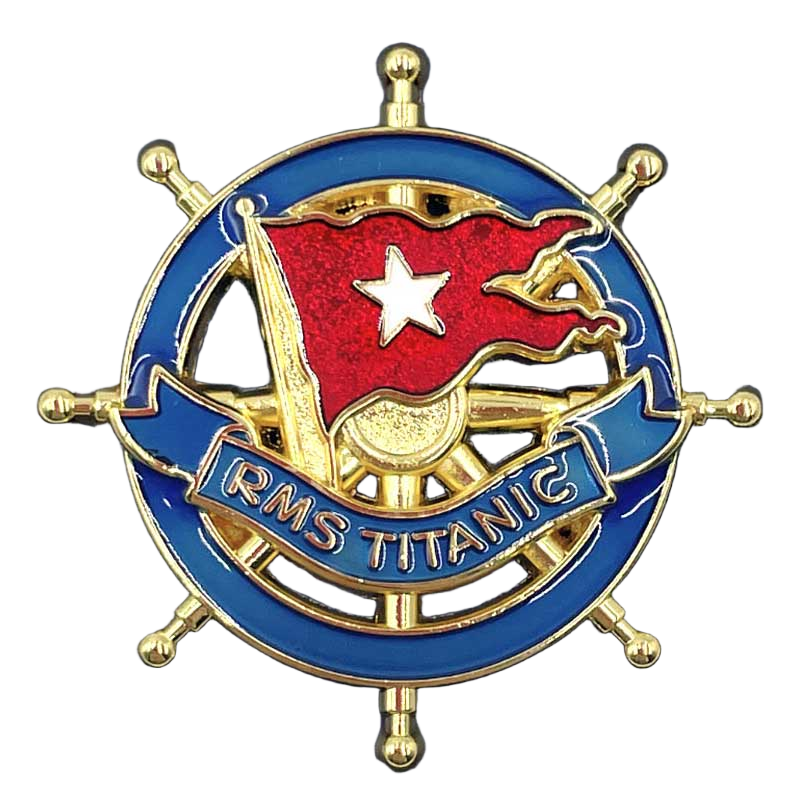

Factor 3: Personalization and Data Management Complexity

custom flag pins RMS Titanic

-

Variable Data Printing: If you require different names, titles, and photos printed on each badge (common for custom ID badges for employees), this is considered variable data. This increases the cost due to the complex digital preparation and print verification required for each unique piece.

-

Color Count: For enamel or baked paint processes, the more individual colors required by your design, the higher the labor cost for accurate color matching and filling.

Factor 4: Back Attachments and Finishing

Choosing-the-Right-Magnetic-Clasp

A simple pin back is the most economical option. Choosing a magnetic clip (for ease of use and protecting clothing) will increase the unit cost due to the higher material cost and more complex installation process. Additionally, requests for extra protective finishes (like clear epoxy coating) or specialized packaging will influence the final quote.

Factor 5: Delivery Timeline Requirements

factory-06

Our standard lead time is designed for efficiency, often offering 15-day fast delivery after design confirmation. If you require an express turnaround, additional fees may apply to cover overtime and priority allocation on the production line.

Industry Insight: The Advantage of Non-Chip ID Badges

You may notice that our metal badges do not include complex RFID or NFC chip functionalities. For many organizations, this is a significant advantage:

-

Aesthetic Purity: By focusing solely on zinc alloy enamel/baked paint craftsmanship, we are free from the constraints of embedding electronics, allowing us to create more intricate, visually appealing, and design-forward ID badges.

-

Ultimate Cost Control: You avoid the high costs associated with chip sourcing, encoding, and technical integration testing. This ensures you get maximum value for high-quality, purely visual identification badges where door access is not required.

If your organization needs high-quality, visually striking metal or acrylic custom ID badges for employees, contact us today. We offer complimentary design services, transparent factory-direct pricing, and our commitment to 15-day fast delivery is your guarantee of quality and speed.