When it comes to belts, the buckle is not just a functional element but also a fashion statement. Custom buckles for belts can elevate your style and give your accessories a personal touch. Whether you’re looking for something unique for your brand, a special gift, or a custom design for a specific outfit, the possibilities are endless. In this guide, we will explore everything you need to know about custom buckles for belts, from the materials used, design options, to the manufacturing process. This comprehensive article will also answer frequently asked questions to help you make informed decisions.

What Are Custom Buckles for Belts?

A custom buckle for a belt is a personalized, unique, and often intricately designed clasp used to fasten a belt. Unlike standard, mass-produced buckles, custom buckles are tailored to individual preferences, including specific designs, logos, shapes, and sizes. Customization allows you to express individuality, creativity, and brand identity, making them ideal for personal use, promotional items, or corporate gifts.

Types of Custom Buckles for Belts

Custom belt buckles come in a variety of styles, materials, and finishes. Some common types include:

- Traditional Belt Buckles: Typically made from metal and featuring a classic design.

- Western-style Buckles: Often larger and more decorative, featuring intricate engraving or designs related to Western themes.

- Logo Buckles: Custom-designed to feature a logo or branding, perfect for companies or promotional events.

- Designer Buckles: Crafted with high-end materials and custom patterns for fashion-forward designs.

- Eco-friendly Buckles: Made from sustainable or recycled materials for a green, eco-conscious option.

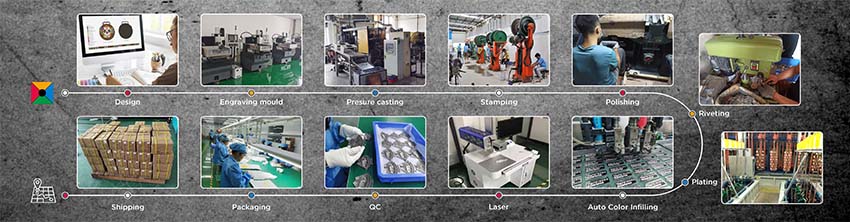

custom process workflow

Materials Used in Custom Buckles for Belts

The material used for creating custom buckles plays a significant role in both the aesthetic and durability of the finished product. Below are the most popular materials used in custom belt buckles:

| Material | Characteristics | Best For |

| Brass | Durable, highly resistant to corrosion,

and has an antique finish. |

Classic designs, vintage look. |

| Stainless Steel | Strong, rust-resistant, and sleek in appearance.

Offers a modern, shiny finish. |

Contemporary styles, corporate branding. |

| Zinc Alloy | Lightweight, versatile, and cost-effective.

Can be molded into various shapes and designs. |

Budget-friendly custom designs, promotional items. |

| Copper | Provides a warm, reddish-brown finish that ages well

and develops a patina over time. |

Vintage, rustic-themed designs. |

| Aluminum | Light and affordable, ideal for larger buckles without

adding weight. |

High-volume production, custom logos. |

| Plastic | Cost-effective and versatile, though less durable than

metal options. |

Promotional items, budget designs. |

Design Options for Custom Buckles for Belts

The beauty of custom buckles lies in their ability to be tailored to your exact specifications. You can choose from a range of design options, such as:

- Engraved Designs: Add intricate text, logos, or images to the buckle using engraving techniques.

- 3D Molded Designs: Create three-dimensional designs with depth and texture, adding a unique touch to your buckle.

- Inlaid Materials: Incorporate precious metals, stones, or enamel to elevate the look of your custom buckle.

- Custom Shapes: Choose non-standard shapes that reflect your personal style or business identity. Popular shapes include hearts, stars, animal figures, and geometric patterns.

- Color Finishes: Select from a variety of finishes such as matte, glossy, brushed, or antique to achieve the desired aesthetic.

The Manufacturing Process of Custom Buckles for Belts

Creating custom buckles for belts involves several steps, from the initial design concept to the final product. Below is a detailed breakdown of the typical manufacturing process:

1. Design Concept

The process starts with a design concept. This could come from you, the customer, or from a designer who works closely with you to bring your ideas to life. You’ll select the material, design, and size, and communicate any additional customizations such as engraving or inlaying.

2. Prototype Creation

Once the design is finalized, a prototype of the buckle is created. The prototype helps you visualize the design and make any necessary changes before mass production begins. It also allows you to evaluate the material and finish.

3. Mold Creation (For Metal Buckles)

For metal buckles, a mold is created based on the prototype. The metal is then poured into the mold to form the shape of the buckle.

4. Finishing Touches

Once the buckle shape is formed, finishing processes such as polishing, coating, or adding enamel are applied. The buckle may also undergo engraving or additional treatments to achieve the desired appearance.

5. Quality Control

Before being shipped, each custom buckle undergoes quality control to ensure it meets the required standards in terms of durability, finish, and design accuracy.

6. Packaging and Shipping

Finally, the custom buckles are packaged securely to ensure safe delivery to the customer.

Benefits of Custom Buckles for Belts

- Personalization: Custom buckles allow for a high level of personalization, from engraving initials to adding logos or custom artwork.

- Branding: Custom buckles with logos are a great way to create branded merchandise, making them perfect for companies or promotional events.

- Unique Design: Stand out from the crowd with a belt buckle that is uniquely yours.

- High-Quality Craftsmanship: Custom buckles are often crafted with more attention to detail than mass-produced buckles, ensuring superior quality.

Common Questions About Custom Buckles for Belts

1. How long does it take to make a custom buckle for a belt?

The manufacturing time for custom buckles typically ranges from 2 to 6 weeks, depending on the complexity of the design and order volume. However, factors such as material availability and design revisions can affect the timeline.

2. Can I create a buckle with my company logo?

Yes, you can create a custom buckle featuring your company logo. This is a popular choice for businesses looking to use custom buckles as promotional items or corporate gifts. Logo buckles can be engraved, stamped, or molded into the design.

3. Are custom buckles durable?

Yes, custom buckles are typically made from high-quality materials such as brass, stainless steel, or zinc alloy, making them durable and long-lasting. The durability depends on the material selected and the craftsmanship of the manufacturer.

4. Can I order custom buckles in bulk?

Yes, custom buckles are available in bulk orders. Many manufacturers offer discounts for bulk purchases, making it an affordable option for businesses, events, or promotional giveaways.

5. Are custom buckles suitable for all belt types?

Custom buckles can be designed to fit most belt types. Whether you’re looking for a traditional leather belt, a canvas strap, or a high-end designer belt, custom buckles can be crafted to complement the style and functionality of the belt.

Conclusion

Custom buckles for belts are the perfect way to add personality, style, and functionality to your accessories. Whether you’re designing a buckle for personal use, promoting your business, or creating a unique gift, the possibilities are endless. With various materials, designs, and finishes available, you can create a one-of-a-kind buckle that is both durable and aesthetically pleasing.

By understanding the materials, design options, and the manufacturing process, you can make an informed decision when creating your custom belt buckles. Don’t hesitate to explore the endless customization options to create a buckle that perfectly matches your needs and personal style.