In the competitive world of custom pin and name badge manufacturing, precision, durability, and design fidelity are non-negotiable. Whether you’re creating branded corporate name badges, commemorative event pins, or personalized accessories, one process stands out as the backbone of quality: laser engraving.

For manufacturers like [Your Company Name], laser engraving isn’t just a step in production—it’s the key to transforming raw materials into intricate, long-lasting custom pins and name badges that exceed client expectations. Let’s break down why laser engraving is indispensable, how it works, and why it matters for your next project.

What Is Laser Engraving in Custom Badge Production?

Laser engraving is a subtractive manufacturing process that uses focused laser energy to etch or mark a design onto a material surface. In the context of custom pins and name badges, it’s the step where your client’s vision—whether a logo, text, or graphic—moves from a digital file to a tangible, permanent feature on the final product.

Unlike traditional methods (e.g., mechanical stamping or chemical etching), laser engraving offers unmatched precision, versatility, and consistency. It’s ideal for small-batch custom orders, intricate designs, and materials like metal (brass, zinc, aluminum), plastic, or even leather—common materials in badge production.

Why Laser Engraving Matters for Custom Pins & Name Badges

Before diving into the technical details, let’s highlight why laser engraving is a game-changer for manufacturers and their clients:

1. Unrivaled Precision: Laser beams can focus on areas as small as 0.1mm, making them perfect for tiny text, fine lines, or complex patterns (e.g., corporate logos with intricate details).

2. Durability: Laser-engraved marks are permanent—they resist fading, scratching, and wear, even with daily use. This is critical for name badges or event pins meant to last for years.

3. Material Versatility: Laser engraving works on nearly any material used in badge production, from soft plastics to hard metals, without damaging the base material.

4. Speed & Scalability: Modern laser systems automate the process, allowing rapid turnaround times—even for custom orders with unique designs.

The Laser Engraving Process: From Design to Final Product

Let’s walk through how laser engraving fits into the custom pin/name badge production workflow at [Your Company Name]:

Step 1: Design Finalization

Every project starts with a client’s design file (typically vector formats like AI, EPS, or SVG). Our team verifies the design’s compatibility with laser engraving—ensuring lines are thick enough, colors contrast with the material, and details are scalable for the final badge size.

Step 2: Material Preparation

Raw materials (e.g., metal sheets, plastic blanks) are cut to size using CNC machines or laser cutters. For metal badges, we often pre-polish or coat the surface to enhance laser absorption and final finish.

Step 3: Laser Engraving Execution

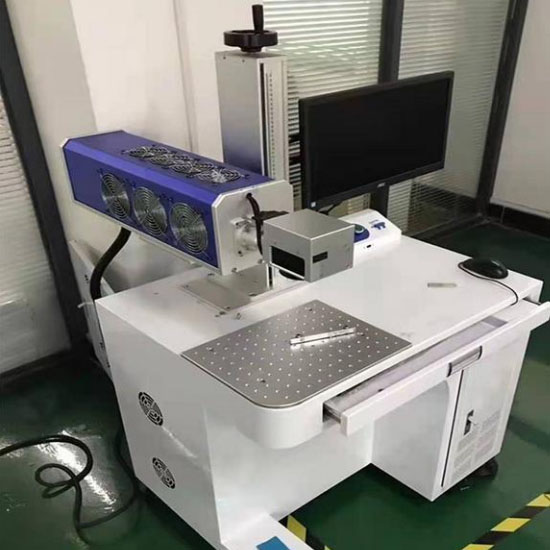

Using a laser marking machine (our go-to tool for precision), the design is “burned” into the material. Here’s how it works:

• A high-energy laser beam is directed onto the material surface.

• The laser’s heat vaporizes or ablates the top layer of the material, creating a visible depression (engraved area).

• The contrast between the engraved area and the untouched surface produces a sharp, visible mark.

For colored or decorative finishes, we may combine laser engraving with secondary processes (e.g., pad printing, plating, or painting) to add depth or color to the design.

Step 4: Quality Inspection

After engraving, every badge undergoes rigorous quality checks. We verify:

• Accuracy of the design (no misalignment or missing details).

• Depth and consistency of the engraving (ensuring durability).

• Surface finish (smooth edges, no burrs or damage).

Laser Engraving vs. Traditional Methods: Why It’s Superior

To understand why laser engraving is the gold standard, let’s compare it to older techniques:

| Aspect | Laser Engraving | Mechanical Stamping/Chemical Etching |

|---|---|---|

| Precision | Sub-millimeter accuracy; ideal for micro-designs. | Limited by tool wear; struggles with fine details. |

| Material Waste | Minimal (non-contact process); no tooling costs. | High (tool setup, material scrap). |

| Customization | Unlimited design flexibility (no tool changes). | Requires new dies/tools for each design change. |

| Durability | Permanent; resistant to wear. | May fade or chip over time (especially on soft metals). |

Choosing the Right Laser Engraving Partner for Your Badges

Not all laser engraving systems are created equal. When partnering with a custom pin/name badge manufacturer, ensure they:

• Use industrial-grade laser machines (e.g., fiber lasers for metals, CO₂ lasers for plastics) tailored to your material.

• Have experience with small-batch, high-mix production (critical for personalized orders).

• Offer post-engraving finishing services (e.g., plating, coloring) to elevate your badge’s aesthetics.

Final Thoughts

Laser engraving is far more than a technical step—it’s the cornerstone of quality in custom pin and name badge manufacturing. By combining precision, versatility, and durability, it transforms client ideas into tangible, long-lasting products that stand out.