In the world of custom medal awards, the difference between a basic design and a standout piece often lies in the details—specifically, the accessories that enhance functionality, aesthetics, or interactivity. From electronic components that add smart features to decorative elements that elevate visual appeal, these accessories are critical to creating medals that align with your brand or event’s unique identity.

For manufacturers and clients alike, understanding which accessories are available, how they’re assembled, and how to select the right ones is key to delivering or acquiring a high-quality custom medal. In this guide, we break down the most common types of medal accessories, their fixation methods (adhesive vs. screw), and actionable tips for choosing the best components for your project.

Accessories for Custom Medal Awards

Why Accessories Matter in Custom Medal Awards

Accessories transform a simple alloy medal into a multifunctional or visually striking keepsake. They can:

• Enhance Functionality: Add features like LED lights, sound modules, or NFC chips for interactive use.

• Boost Aesthetics: Introduce color, texture, or dimensional details that complement the medal’s main design.

• Improve Durability: Reinforce weak points or protect vulnerable areas (e.g., electronic components).

Common Accessories for Custom Medal Awards

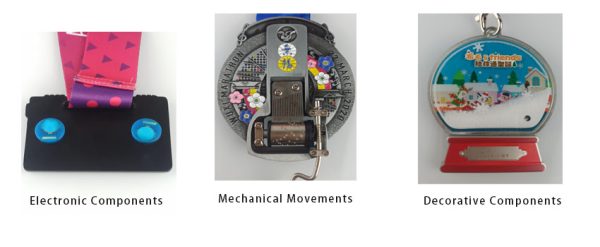

Most custom medal accessories fall into three categories: electronic components, mechanical parts, and decorative elements. Below, we detail their uses, materials, and ideal applications.

1. Electronic Components

Electronic accessories are ideal for modern, tech-forward medals, such as event badges, award trophies, or promotional items.

Examples:

• LED Lights: Miniature LEDs (light-emitting diodes) for backlighting logos or text (e.g., red/green indicator lights for achievement milestones).

• Sound Modules: Small speakers or buzzers that play melodies or voice recordings (e.g., a “congratulations” message when the medal is touched).

• NFC Chips: Near-field communication tags for digital interaction (e.g., scanning to access a recipient’s profile or event details).

Materials: Silicone-coated circuits, lithium batteries (for power), and waterproof casings (to protect against moisture).

Fixation Method: Typically secured with epoxy adhesive (for small, lightweight components) or micro-screws (for heavier or vibration-prone parts).

2. Mechanical Movements

For medals requiring dynamic features—such as rotating elements, sliding panels, or mechanical animations—precision movements (small mechanical parts) are essential.

Examples:

• Rotating Bezel: A circular movement that spins to reveal hidden text or images (common in commemorative sports medals).

• Sliding Mechanism: A track system that moves a panel to display a secondary design (e.g., a “before/after” achievement timeline).

• Spring-Loaded Clips: Small springs that secure detachable parts (e.g., a removable ribbon or charm).

Materials: Stainless steel, brass, or zinc alloy (for strength and corrosion resistance).

Fixation Method: Most often attached with screws (to ensure tight, wobble-free alignment) or industrial adhesive (for low-profile, non-removable parts).

3. Decorative Components

Decorative accessories focus on enhancing the medal’s visual appeal, often aligning with the event’s theme or brand identity.

Examples:

• Acrylic Parts: Colored or clear acrylic inserts for layered designs (e.g., a translucent emblem over a metallic background).

• Enamel Inlays: Hand-painted or printed enamel tiles for vibrant, textured details (common in military or organizational awards).

• Gemstones/Resin Accents: Small crystals, rhinestones, or resin domes for a luxurious finish (popular in luxury brand medals).

Materials: Acrylic sheets, enamel paints, or resin compounds (depending on the design).

Fixation Method: Usually bonded with clear-drying adhesive (to avoid discoloration) or ultrasonic welding (for seamless integration with metal surfaces).

Fixation Methods: Adhesive vs. Screw

The choice between adhesive and screw fixation depends on the accessory’s size, weight, and function. Here’s a comparison to guide your decision:

Factor Adhesive Fixation Screw Fixation

Suitable for Lightweight, small accessories (e.g., LEDs, acrylic inlays). Heavy-duty or removable parts (e.g., movements, gemstones).

Durability Good for static, non-vibrational use. Superior for dynamic or frequently handled parts.

Aesthetics Seamless (no visible hardware). Visible screws (may require covering with plugs).

Assembly Time Quick (no tooling). Slower (requires drilling/aligning holes).

How to Choose the Right Accessories for Your Medal Award

To ensure your custom medal meets both functional and design goals, follow these steps:

1. Define the Medal’s Purpose:

• Award/Trophy: Prioritize decorative and durable accessories (e.g., enamel inlays, screw-fixed movements).

• Promotional Item: Focus on cost-effective, eye-catching accessories (e.g., colored acrylic parts, adhesive LEDs).

• Tech-Enabled: Invest in electronic components with reliable fixation (e.g., NFC chips with epoxy adhesive).

2. Match Accessories to Material:

• Metal alloys (brass, zinc): Pair with stainless steel screws or industrial adhesive (resistant to corrosion).

• Plastic/resin medals: Use silicone-based adhesives to avoid damaging the base material.

3. Test for Durability:

• For medals intended for daily wear (e.g., employee awards), conduct stress tests (e.g., bending, scrubbing) to ensure accessories stay fixed.

Why Partner with a Manufacturer Specializing in Medal Accessories?

At [Your Company Name], we integrate accessory selection into every stage of custom medal production:

• Precision Manufacturing: We source and fabricate accessories to tight tolerances (±0.1mm) for seamless integration.

• Adhesive Expertise: Our team tests epoxy, silicone, and ultrasonic welding methods to match your medal’s material and use case.

• Custom Solutions: Need a unique accessory shape or material? We offer custom molding (e.g., 3D-printed plastic parts) and private labeling.

Final Thoughts

Accessories are the unsung heroes of custom medal awards—they transform functional designs into memorable, functional, and visually stunning pieces. By understanding the types of accessories available, their fixation methods, and how to align them with your medal’s purpose, you’ll deliver a product that recipients will cherish for years.

Ready to create your next custom medal award? # to discuss your design, material, and accessory needs—we’re here to bring your vision to life with precision and expertise.