Crafting Excellence: Why Die Cast Medals Are the Superior Choice for Your Custom Awards

I. Introduction: The Critical Choice in Custom Award Crafting

Every exceptional event or corporate recognition deserves a medal that truly reflects its prestige. The decision you make regarding the manufacturing technique is pivotal, directly influencing the medal’s quality, visual impact, and enduring value. While there are two primary methods—die casting and die stamping—it is the process of die casting that consistently delivers the greatest advantage for intricate, high-quality designs. This comprehensive guide will illuminate the specific benefits of choosing die cast medals, helping you make the most informed procurement decision.

die-cast-medal-vs-stamping-medals

II. In-Depth Comparison: Understanding the Fundamental Differences

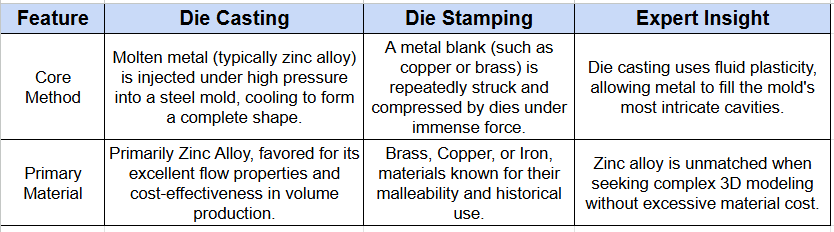

Making the right choice starts with understanding how the medal is actually created. This comparison highlights the core distinctions that impact your final product.

2.1 Manufacturing Principle and Material Suitability

stamping-medal-mold

die casting vs stamping

2.2 Design Freedom and Three-Dimensional Superiority

This is where the choice of die cast medals truly shines, offering creative capabilities that simpler manufacturing methods, like die stamping, cannot match.

custom race medals 3D

-

Unrivaled 3D Relief and Depth: Die casting allows you to achieve high-precision, multi-layered three-dimensional relief and depth. If your logo or design requires genuine tactile layering, steep angles, or recessed areas, the die cast method is essential. It enables the creation of truly lifelike textures and complex geometrical features.

Custom Summer Solstice 10KM Finisher Medals for Awards -2

-

Intricate and Irregular Shapes: When you move beyond simple circular or rectangular medals, the limitations of die stamping become apparent. Custom die cast medals easily accommodate irregular edges, internal cutouts, negative spaces, and highly complex silhouettes, preserving your original creative vision without compromise.

Custom Award Medals for Mother’s Day Runs -2

-

Exceptional Detail Resolution: For designs involving small text, complex coats of arms, or subtle graphic elements, die casting ensures that every minute detail is captured with sharp, clean lines. The high-pressure injection process forces the metal into every crevice of the mold.

2.3 Quality, Feel, and Efficiency for Large Orders

-

The thickness of the stamped parts is between 1.8 and 2.5 mm.but zinc alloy die casting generally supports thicknesses of 1.5-3.0mm. Die cast medals generally possess a superior density and thickness, providing a satisfyingly heavier, more substantial feel in the hand. This weight conveys a sense of quality and high perceived value, making the award truly memorable.

-

Reliable Volume Production: Once the initial mold is perfected, the die casting process is highly repeatable and scalable. This allows for efficient, high-volume manufacturing, ensuring consistency across thousands of pieces—a critical factor for major events or large annual programs.

III. Your Procurement Questions Answered: Our Service Commitment

We understand that purchasing custom awards involves more than just selecting a technique; it requires confidence in your manufacturing partner. Here is our commitment to you:

3.1 Cost and Order Volume

-

Q1: What is the Minimum Order Quantity (MOQ) for custom die cast medals?

-

A: To support diverse needs, our Minimum Order Quantity (MOQ) is only 100 pieces.

-

-

Q2: What is your policy regarding mold fees?

-

A: The mold fee is a one-time setup cost. We value repeat business: if you reorder a substantial volume within three years of the initial purchase, the mold fee may be waived or fully credited against your new order.

-

3.2 Color Accuracy and Quality Assurance

-

Q3: How do you guarantee the accuracy and consistency of colors?

-

A: We use the industry-standard Pantone Matching System (PMS) to ensure precise color matching. All enamel filling is meticulously applied according to your specified Pantone references, guaranteeing uniformity across all production batches.

-

-

Q4: How do you ensure the quality of the finished product?

-

A: We will produce a pre-production sample and take photos and videos for your confirmation before proceeding with mass production, ensuring everything is perfect.

-

3.3 Process, Efficiency, and Expert Support

-

Q5: What is the typical lead time from design finalization to delivery?

-

A: After the final design is approved (and sample confirmed, if required), we commit to completing mass production and shipping within 15 business days. Our reliable supply chain ensures we meet your event deadlines.

-

-

Q6: Can you assist if we don’t have a finalized design file?

-

A: Absolutely. We employ a specialized in-house design team ready to provide complimentary design services, including revisions and professional optimization suggestions, until you are completely satisfied with the artwork for your custom die cast medals.

-

IV. Conclusion: Your Partner in Premium Recognition

Choosing the die cast method is choosing superior design expression, quality, and a more robust medal. By partnering with us, you gain access to expert knowledge, transparent processes, and the commitment to transform your vision into an exceptional, lasting award. We look forward to crafting your next recognition piece.