Introduction: Beyond the Business Card—The Power of Promotional Keychains

In today’s competitive market, a generic handout won’t capture attention. You need a marketing tool that offers continuous brand exposure and genuine utility. That’s where promotional keychains excel. For businesses looking for high-impact, low-cost merchandise, mastering the art of wholesale custom keychains procurement is essential for maximizing return on investment (ROI). This guide provides strategic insights straight from our production floor, specifically tailored to optimize your bulk order.

UV 3D Printing Unleashing Color Freedom for Your Custom 3D Printed Keychain

Part 1: Core Decisions Before Placing Your Bulk Order (Minimizing Risk)

Entering the world of custom keychains bulk ordering requires strategic planning to ensure efficiency, quality, and cost savings.

1.1 Price vs. Quantity: Our Tiered Bulk Pricing & Mold Fee Policy

The unit cost of your product is highly dependent on volume. We employ a tiered pricing structure that rewards scale. Crucially, we offer an exceptional incentive for long-term partners: The mold fee will be waived for any re-order of the same design placed within 3 years. This policy transforms the initial mold cost into a one-time investment, securing a significantly lower unit price for all future wholesale custom keychains runs.

1.2 Design Artwork: Free Professional Support & Color Precision

Upload-your-design-draft-our-customization-specialists-will-provide-you-with-digital-previews-of-both-hard-enamel-and-soft-enamel-versions.

To guarantee a precise, high-fidelity reproduction of your custom keychains with logo, professional file preparation is vital.

-

Design Solution: If you do not possess the necessary vector files (AI, CDR), our specialized design team is here to help! We offer free professional design services to create production-ready artwork based on your initial ideas, sketches, or low-resolution files.

-

Color Standard: To ensure absolute consistency and prevent color deviation, we exclusively utilize the internationally unified Pantone color card for color matching all promotional keychains.

1.3 Strategic Timeline Management: Faster Delivery Times

factory-06

Timeliness is paramount for custom keychains bulk orders, especially those tied to events. We adhere to clear, industry-leading timelines:

-

Sampling: After design confirmation, the sample lead time is typically 7–10 days.

-

Production Delivery: Following sample approval, the mass production and delivery cycle is efficiently managed within 15–18 days.

Part 2: Factory Cost Strategy—Our Zinc Alloy Advantage

Leveraging our factory insights helps you make economical choices without sacrificing quality.

2.1 Mold Fee Investment and Re-order Savings

high-precision molds-engrave-making

We view the mold fee as an investment in a three-year partnership. By offering the free mold re-order policy for three years, we significantly reduce your subsequent purchasing costs, allowing you to secure the best wholesale custom keychains pricing without penalty for holding inventory.

2.2 Material Advantage and Bulk Cost Analysis

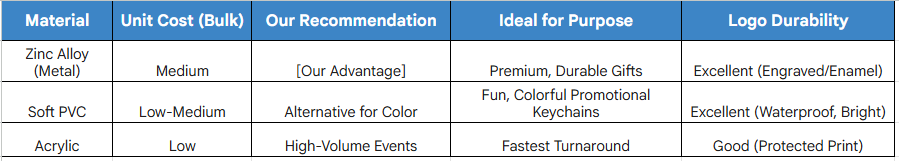

While we offer various materials, we strongly recommend our specialized Zinc Alloy material. This is a core factory advantage that allows us to deliver lower MOQ, lower cost, and faster delivery time for a premium metal feel.

Below is a comparative glance at popular bulk materials:

a comparative glance at popular bulk materials

This makes Zinc Alloy an ideal choice for durable, high-quality custom keychains bulk orders.

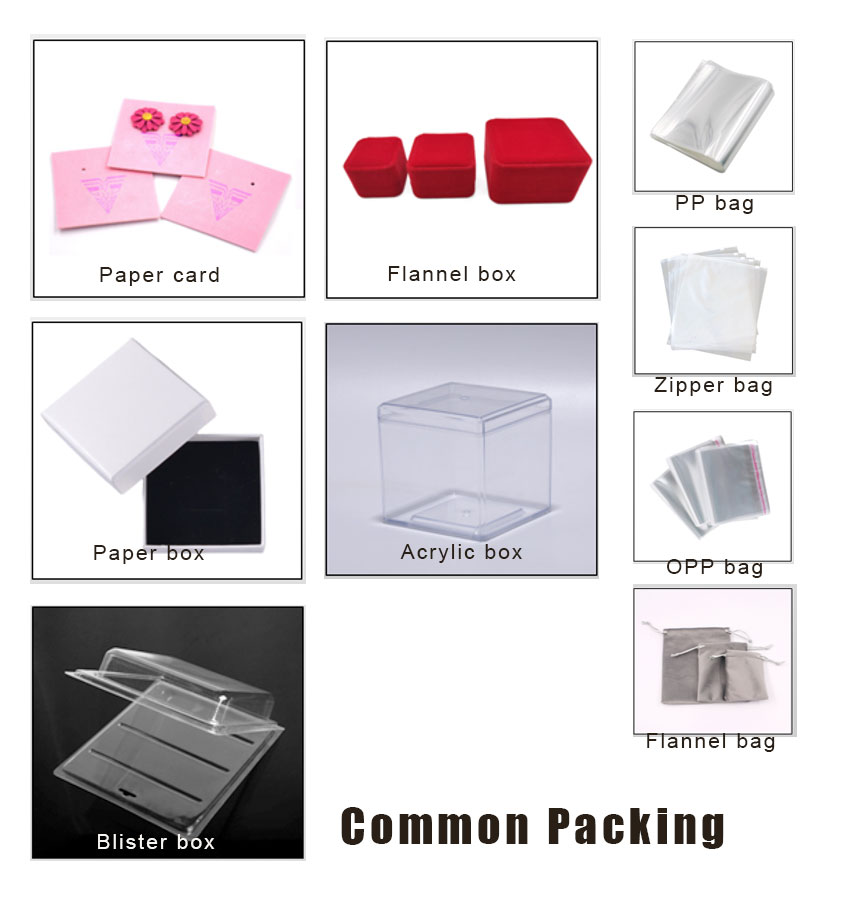

2.3 Packaging and Logistics: Customizing Your Presentation

common-packing

Beyond basic bulk packaging, we understand that presentation matters. We provide customized design services for various packaging materials—from elegant gift boxes and custom hang tags to blister packaging—ensuring your wholesale custom keychains meet diverse market requirements and enhance perceived value.

Part 3: Perfecting Your Custom Keychains with Logo & Event Strategy

The keychain’s purpose determines the best method for applying your brand.

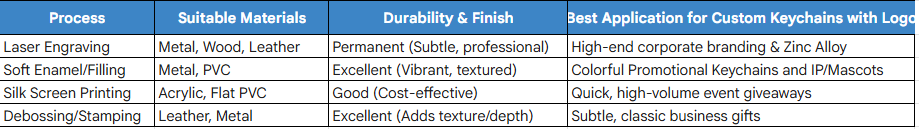

3.1 Expert Comparison: Four Main Logo Customization Techniques

Choosing the right application for your custom keychains with logo dictates aesthetics and longevity. We guide you through the pros and cons based on your material choice and desired durability for your promotional keychains.

Four Main Logo Customization Techniques

3.2 Activity-Oriented Keychain Selection

Maximize the impact of your promotional keychains by aligning them with your marketing goals:

-

Brand Exposure (Trade Shows): Opt for low-cost, high-contrast, visually appealing designs.

-

Customer Loyalty (Client Gifts): Choose premium materials like our Zinc Alloy with a laser-engraved custom keychains with logo to convey lasting value.

-

Digital Engagement: Integrate features like NFC chips or QR codes into your promotional keychains for quick link sharing.

Part 4: Establishing Long-Term Partnership & Quality Assurance

Trust is built on transparency and consistent quality in wholesale custom keychains.

4.1 Transparent Quality Control (QC) & Reporting

police-badge-maker-production-process

To ensure your entire custom keychains bulk order meets our high standards, our Quality Control process is fully transparent: Our dedicated sales personnel provide detailed progress reports and photo feedback at every critical production stage (e.g., molding completion, initial batch printing, final assembly). This proactive reporting eliminates guesswork and confirms the quality of your custom keychains bulk investment before shipment.

4.2 Dedicated Account Management & After-Sales Support

Your wholesale custom keychains order is managed by a dedicated account specialist, ensuring clear communication and immediate support. This commitment to partnership, backed by our 3-year mold policy and in-house expertise, solidifies our relationship as your trusted manufacturing partner.

Conclusion: Partner with Us for Your Bulk Custom Keychains

Ready to benefit from our Zinc Alloy expertise, free design service, and reliable production timelines? By leveraging our factory’s advantages—from competitive pricing and the 3-year mold policy to transparent QC—you are guaranteed the highest quality wholesale custom keychains on the market.

Contact us today for a free quote and let our factory’s efficiency transform your next promotional keychains campaign!