How to Make Custom Pin Badges: Hard Enamel, Soft Enamel, or Print? The Ultimate Guide to Choosing Your Finish

Introduction: Your Design, Our Expertise

You have a fantastic design idea for a pin badge—maybe it’s a new corporate logo, a piece of fan art, or merchandise for your brand. The next, and most crucial, step is deciding on the right manufacturing process. The finish you choose determines everything: the badge’s texture, its perceived value, the level of detail, and ultimately, your project’s budget.

When you search for how to make custom pin badges, you quickly encounter three main options: Hard Enamel, Soft Enamel, and Printed. As experienced custom pin badges manufacturers, we’re here to break down the differences and help you translate your vision into the perfect physical product.

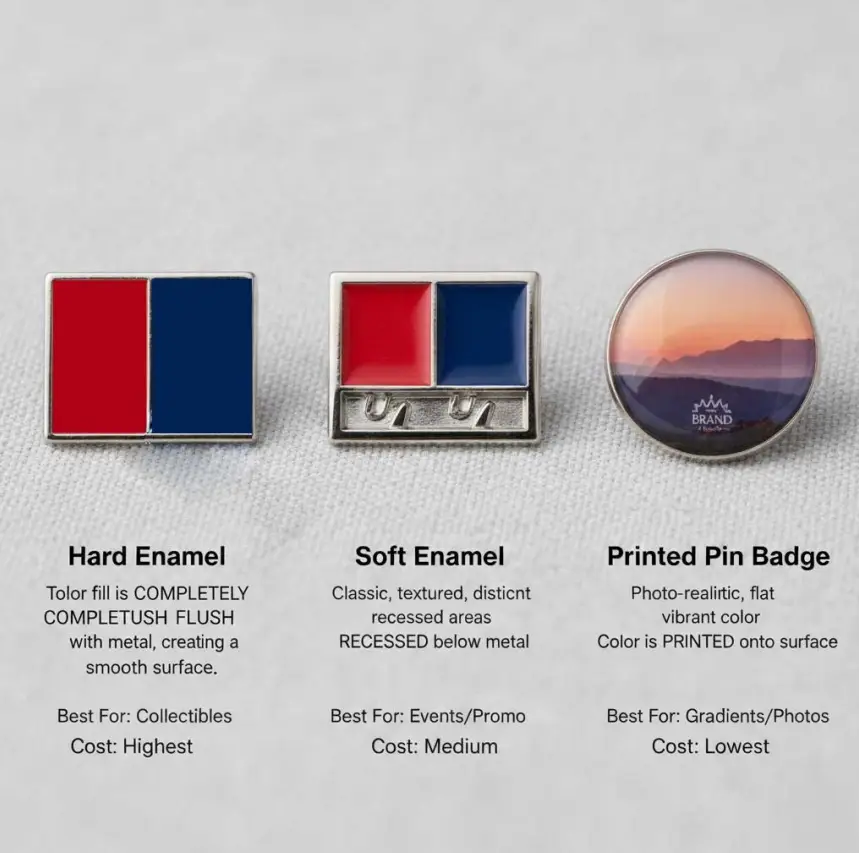

Part I: Quick Comparison—Choosing Your Finish

Quick Comparison—Choosing Your Finish

Before diving into the technical details, here is a rapid overview to help you align your design goals with the right material:

| Feature | Hard Enamel | Soft Enamel | Printed Pin Badges |

| Look & Feel | Top-tier, smooth, jewelry-like finish | Classic, textured,

distinct recessed areas |

Photo-realistic, flat,

vibrant color |

| Color Position | Color fill is flush (level) with

the raised metal lines. |

Color fill is recessed (lower)

thanthe metal lines. |

Color is printed onto

the metal surface. |

| Best For | Clean color blocks, high perceived value,

collectibles. |

Clean color blocks,

metallic dimension, budget efficiency. |

Gradients, photographic detail,

complex color schemes. |

| Cost | Highest

(due to extra polishing) |

Medium

(most popular option) |

Lowest

(fastest production method) |

Part II: In-Depth Look at the Three Main Processes

Understanding the mechanics of each option will allow you to confidently order your custom pin badges.

2.1 Hard Enamel Pin Badges: The Premium, Collector’s Choice

custom enamel pins Alice

-

Process Detail: After the colors are applied, the badge is fired at an extremely high temperature and then polished multiple times. This extra step grinds the color and the surrounding metal lines to be perfectly level with one another.

-

Design Effect: The result is a seamless, highly durable, and polished surface—it feels like a fine piece of jewelry. It is highly resistant to scratching and wear, making it the ideal choice for creating collectible custom pin badges.

-

Best Suited For: Employee service awards, luxury brand merchandising, exclusive limited-edition collectibles, or designs prioritizing sleekness.

-

Key Limitation: Due to the polishing process, it cannot accommodate complex gradients or very fine, delicate lines.

2.2 Soft Enamel Pin Badges: The Classic Textured Look

custom flag pins RMS Titanic

-

Process Detail: This is the most popular and versatile technique for making custom pin badges. Colors are filled into recessed areas and cured without the final polishing step.

-

Design Effect: The defining characteristic is the textured, dimensional look. You can clearly feel the raised metal lines surrounding the recessed, bright enamel colors. This visual contrast is highly desirable for creating fun, noticeable pop-culture merchandise.

-

Best Suited For: Promotional giveaways, fan merchandise, school or team badges, and projects requiring the best balance between quality, speed, and cost.

-

Key Limitation: The recessed color areas are slightly more vulnerable to debris build-up, and the surface is not smooth like hard enamel.

2.3 Printed Pin Badges: The Detail and Color Specialist

Unique movable Kungfu pin as souvenir (5)

-

Process Detail: Your design is either silk-screened or digitally (offset) printed directly onto the metal surface. A clear epoxy dome is then applied over the top to protect the image.

-

Design Effect: If your design features photographic detail, subtle color gradients, or extremely small text, this is your only viable option. Since there are no metal lines separating colors, the color freedom is limitless.

-

Best Suited For: Designs with intricate color blending, complex illustrations, and budget-sensitive projects where high-fidelity color is more important than traditional texture.

-

Key Limitation: These custom pin badges lack the traditional, sturdy feel of die-struck metal. They are flat, and while the epoxy dome protects the print, they don’t have the tactile depth of enamel.

Part III: Making the Right Choice for Your Brand

To help you decide which process is right for your next custom pin badges order, consider these three critical factors:

3.1 Base Your Choice on Design Complexity

-

If your design includes gradients, photography, or ultra-fine details: Choose Printed Pin Badges.

-

If your design relies on clear color blocking and prominent metal lines: Choose Soft Enamel or Hard Enamel.

3.2 Base Your Choice on Budget and Value

-

For the highest perceived value and a higher budget: Opt for Hard Enamel.

-

For the best quality-to-price ratio and high volume: Soft Enamel is the industry standard.

-

For lowest cost and fastest turnaround (where color complexity is key): Choose Printed Pin Badges.

3.3 Base Your Choice on Brand Positioning

-

High-End, Corporate, or Legacy Brands: Hard Enamel signals permanence and luxury.

-

Pop Culture, Events, or Fun, Playful Brands: Soft Enamel offers the best visual pop and dimension.

-

Artistic or Photographic Brands: Printed Pin Badges ensure exact visual fidelity to the original artwork.

Conclusion: Your Pin Badge Partnership Begins Here

factory-01

Choosing the right finish is essential to ensuring your custom pin badges perfectly represent your brand. As an experienced manufacturer, we specialize in perfecting all three techniques.

Don’t let the technical choices overwhelm your creative process. We invite you to leverage our expertise. Contact us today with your design and your budget, and our specialists will recommend the ideal process to ensure your next pin badge project is successful, perfectly finished, and delivered on time.