In today’s competitive marketplace, custom engraved keychains have emerged as one of the most versatile and cost-effective promotional tools available. Whether you’re a business owner looking to enhance brand visibility or an entrepreneur seeking profitable product opportunities, understanding how to make engraved keychains with modern UV printing technology can open doors to countless possibilities.

What Are Engraved Keychains and Why Choose UV Printing?

Definition of Engraved Keychains

Engraved keychains represent the perfect fusion of functionality and personalization. These compact accessories serve dual purposes: they keep your keys organized while showcasing custom designs, logos, or messages that reflect individual style or brand identity. Unlike simple key holders, engraved keychains transform everyday utility items into meaningful keepsakes or powerful marketing tools.

The evolution from traditional engraving methods to modern UV printing has revolutionized keychain customization. Traditional engraving techniques, while still valuable for certain applications, often limit design complexity and color options. In contrast, UV printing technology enables full-color, high-resolution designs that were previously impossible to achieve on small keychain surfaces.

Benefits of UV Printing for Keychains

UV-printing-02

UV printing technology offers unprecedented advantages for keychain customization. The process delivers exceptional print quality with vibrant, full-color reproduction that maintains crisp detail even on miniature surfaces. This high-resolution capability ensures that intricate logos, photographs, or complex graphics translate beautifully onto keychain materials.

The versatility of UV printing extends across multiple substrate options. Whether working with acrylic sheets, stainless steel, aluminum, genuine leather, or various wood types, UV inks adhere effectively to create lasting impressions. This material flexibility allows manufacturers to offer diverse product lines that cater to different aesthetic preferences and budget requirements.

Durability stands as another compelling advantage. UV-cured inks create scratch-resistant surfaces that withstand daily wear and tear. The UV protection inherent in the curing process prevents fading, ensuring that colors remain vibrant throughout the keychain’s lifespan. This longevity makes UV-printed keychains ideal for promotional campaigns where brand visibility must endure extended use.

Tools and Materials Needed to Make Engraved Keychains

Essential Equipment

The foundation of professional keychain production lies in selecting appropriate equipment. A UV flatbed printer serves as the cornerstone of any serious keychain manufacturing operation. These specialized printers accommodate various material thicknesses and provide the precision necessary for small-format printing. When evaluating UV printer options, consider print resolution, material compatibility, and production speed to match your intended output volume.

Complementing the UV printer, a CO2 laser engraver adds valuable capabilities for shaping and cutting base materials. Laser engravers excel at creating precise cuts in acrylic and wood substrates, enabling custom shapes that differentiate your keychains from standard rectangular formats. The combination of laser cutting and UV printing creates unlimited design possibilities.

Materials for Engraved Keychains

Materials for Engraved Keychains

Material selection significantly impacts both production costs and final product appeal. Acrylic sheets remain the most popular choice due to their affordability, durability, and excellent print receptivity. Clear acrylic allows for transparent backgrounds that create sophisticated layered effects, while frosted varieties provide elegant, subdued appearances. Colored acrylics offer additional design possibilities by serving as background tones for printed elements.

Metal substrates, including stainless steel and zinc alloy, appeal to customers seeking premium feel and durability. These materials require specific UV ink formulations and potentially primer applications, but they command higher selling prices and project quality brand images.

Natural materials like wood and leather introduce organic textures that resonate with environmentally conscious consumers. Each material type requires understanding specific preparation and printing parameters to achieve optimal results.

Additional Supplies

Supporting supplies ensure professional results and efficient production workflows. UV-compatible inks and coatings must match your specific printer model and intended substrates. Investing in high-quality consumables prevents printing issues and maintains consistent output quality.

Hardware components including key rings, split rings, and specialty attachments complete the functional aspects of keychain assembly. Consider offering multiple attachment options to serve different customer preferences and use cases.

Protective finishing materials such as epoxy resin or clear protective coatings add durability and premium appearance to finished products. These optional treatments justify premium pricing while ensuring customer satisfaction through extended product life.

Step-by-Step Guide: How to Prepare Custom Designs for UV Printing

Choosing the Right Design Software

Professional design software ensures optimal print results and efficient workflow management. Adobe Illustrator excels for vector-based lo

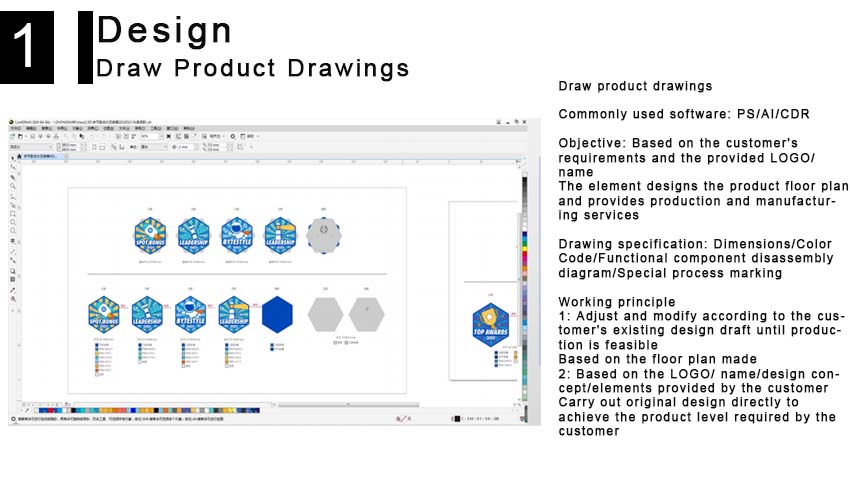

Design draw product drawings

gos and graphics that require scalability without quality loss. CorelDRAW offers similar capabilities with some users preferring its interface for sign and promotional product design. Adobe Photoshop serves photo manipulation and raster image preparation needs.

When learning how to make engraved keychains, mastering at least one professional design platform becomes essential for producing marketable results. Free alternatives exist, but professional tools provide the precision and file format compatibility required for commercial production.

Setting Up the File

Proper file preparation prevents costly printing errors and ensures optimal results. Keychain designs typically require 300 DPI resolution to maintain sharp detail at small sizes. Establish precise dimensions matching your intended keychain size, accounting for any cutting tolerances or safety margins.

Background treatment requires careful consideration. Transparent backgrounds allow substrate materials to show through, creating elegant effects with clear acrylic or natural wood grains. Solid background colors provide consistent appearance but may require additional ink coverage that increases production costs.

Text elements demand special attention due to size constraints. Select fonts that maintain legibility at small sizes, avoiding overly decorative typefaces that may become illegible when printed. Ensure adequate contrast between text and background elements for optimal readability.

Preparing for Printing

File format selection impacts both print quality and production efficiency. PDF files maintain design integrity across different systems and prevent font substitution issues. Adobe Illustrator (.AI) and Encapsulated PostScript (.EPS) formats preserve vector information for scalable elements while supporting embedded raster images.

Color management prevents disappointing results and costly reprints. Establish color profiles that match your printer’s capabilities, whether using Pantone spot colors for brand consistency or CMYK process colors for photographic reproduction. Always conduct test prints using actual production materials before committing to large runs.

How to Make Engraved Keychains with UV Printing Technology

Cutting and Shaping the Base

The process of how to make engraved keychains begins with preparing base materials to exact specifications. Laser cutting provides the precision necessary for professional results, creating clean edges that enhance the overall appearance. When cutting acrylic materials, adjust laser settings to minimize heat-affected zones that could compromise print adhesion.

Edge finishing becomes crucial for both safety and aesthetics. Rough or sharp edges detract from professional appearance and may cause injury. Flame polishing acrylic edges creates glass-like clarity, while sanding and buffing work well for wood and composite materials.

Printing the Custom Design

Material preparation ensures optimal print adhesion and color reproduction. Clean all surfaces thoroughly to remove dust, oils, or residue that could interfere with ink bonding. Some materials benefit from primer application, particularly metals or challenging plastics that may not naturally accept UV inks.

Precise material alignment on the printer bed prevents design placement errors and ensures consistent results across production runs. Most UV printers include positioning aids or templates that streamline this process. Take time to verify alignment before initiating print cycles.

UV curing requires careful attention to exposure times and intensity settings. Under-cured inks may appear dull or peel easily, while over-curing can cause brittleness or color shifts. Follow manufacturer specifications while adjusting for material variations and ambient conditions.

Assembly and Finishing Touches

Professional assembly techniques distinguish quality products from amateur attempts. Attach hardware components securely using appropriate tools and techniques. Split rings require special pliers for safe installation, while screw-together assemblies need consistent torque to prevent loosening.

Optional protective coatings enhance durability and appearance but require careful application to avoid thickness variations or trapped bubbles. Allow adequate curing time between coating application and final packaging to prevent adhesion issues.

Quality control inspections should examine each finished piece for scratches, color inconsistencies, or assembly defects. Establishing consistent standards ensures customer satisfaction and reduces return rates.

Creative Ideas for Custom Engraved Keychains

Business and Brand Merchandise

Corporate logo keychains serve as affordable yet effective brand ambassadors. When designing business keychains, ensure logo reproduction maintains brand guideline compliance while adapting to small format constraints. Consider incorporating contact information or website URLs that provide ongoing marketing value.

Event giveaways and trade show items benefit from unique designs that create memorable impressions. Limited edition designs or event-specific customization increase perceived value and encourage retention. Consider incorporating QR codes that link to digital content or special offers.

Personalized Gifts

Photo keychains tap into the growing demand for personalized products. High-resolution printing capabilities allow reproduction of family portraits, pet photos, or meaningful images. Offer various cropping and enhancement services to optimize photo reproduction within keychain dimensions.

Name and message engraving creates sentimental value that encourages long-term use. Consider offering multiple font options, special characters, or multilingual capabilities to serve diverse customer bases. Date commemoration adds significance for anniversaries, graduations, or milestone celebrations.

Trendy and Niche Designs

Popular culture themes including anime, gaming, and entertainment franchises appeal to passionate fan bases willing to pay premium prices. Stay current with trending topics while respecting intellectual property rights. Original artwork inspired by popular themes provides safer alternatives to direct licensing.

Seasonal and holiday-inspired designs create recurring sales opportunities throughout the year. Develop design libraries that can be quickly customized for different occasions, maximizing design investment returns while serving time-sensitive market demands.

Common Mistakes to Avoid When Making Engraved Keychains

Design Issues

Overly complex details often fail to reproduce effectively at keychain scales. Fine lines may break up or disappear entirely, while intricate patterns can create muddy appearances. Simplify designs while maintaining visual impact through strategic use of contrast and negative space.

Poor color contrast renders text unreadable and diminishes overall design impact. Test color combinations at actual print sizes to verify legibility. Consider colorblind accessibility when selecting color palettes to ensure broad appeal.

Low-resolution images produce pixelated results that appear unprofessional. Always source or create images at sufficient resolution for intended print sizes, accounting for any scaling requirements.

Material Mistakes

Incompatible surface treatments can prevent proper ink adhesion, leading to peeling or flaking. Research material compatibility thoroughly before investing in substrate inventory. Conduct adhesion tests with small samples before committing to large production runs.

Skipping preparation steps like cleaning or priming may seem like time-savers but often result in quality issues that damage reputation and increase costs through reprints or customer complaints.

Production Problems

Printer bed misalignment wastes materials and creates inconsistent results. Develop standard positioning procedures and verification steps to ensure accurate placement. Regular calibration maintains alignment accuracy over time.

Inadequate UV curing leads to premature wear and customer dissatisfaction. Monitor curing lamp condition and replace bulbs according to manufacturer recommendations. Environmental factors including temperature and humidity can affect curing requirements.

Business Value of Custom Engraved Keychains

Business Value

Marketing and Branding Benefits

Custom keychains provide exceptional marketing value through their combination of utility and visibility. Recipients use keychains daily, creating repeated brand exposure that extends far beyond initial distribution costs. The compact size makes them ideal for mailing campaigns, trade show distributions, or customer appreciation gifts.

Brand recall studies consistently demonstrate that useful promotional items create stronger memory associations than passive advertising methods. Keychains rank among the most retained promotional products, ensuring long-term marketing impact.

Retail and E-Commerce Potential

The keychain market offers attractive profit margins for manufacturers who understand production optimization and market positioning. Low material costs combined with premium pricing for customization create sustainable business models. Online platforms enable global reach without significant infrastructure investment.

Customization capabilities allow for premium pricing that significantly exceeds generic keychain values. Offering design services, rush delivery, or exclusive materials justifies higher prices while differentiating from commodity competition.

Emotional Connection with Customers

Personalized keychains create emotional bonds that extend beyond transactional relationships. Gift recipients associate positive feelings with brands that enabled meaningful present giving. This emotional connection translates into customer loyalty and positive word-of-mouth marketing.

Commemorative keychains for events, achievements, or milestones become cherished keepsakes that maintain brand visibility for years. The sentimental value prevents disposal, ensuring extended marketing impact.

Where to Order or Manufacture Custom Engraved Keychains

DIY vs Professional Manufacturing

Understanding how to make engraved keychains in-house provides complete control over quality, timing, and costs. However, equipment investment requirements and learning curves may not justify small-volume needs. Evaluate production volumes, quality requirements, and available resources when deciding between internal production and outsourcing.

Professional manufacturing offers expertise, established quality systems, and economies of scale that may reduce per-unit costs for larger quantities. However, communication challenges and reduced control over production timing require careful vendor selection and relationship management.

Choosing the Right Manufacturer

factory-01

Quality certifications including ISO standards, BSCI compliance, and SGS testing demonstrate manufacturer commitment to consistent results and ethical practices. These certifications provide confidence in production capabilities while meeting corporate responsibility requirements.

Experience with UV printing technology and custom design handling ensures optimal results. Request portfolio examples that demonstrate capability ranges and quality standards. Evaluate communication responsiveness and technical support availability.

How to Get Started

Free design consultation services help optimize artwork for production requirements while identifying potential issues before costly printing begins. Take advantage of these services to improve results and reduce revision cycles.

Sample requests allow quality evaluation before committing to large orders. Most reputable manufacturers provide samples at reasonable costs that can be credited toward production orders. Use sample evaluation to assess material quality, print resolution, and assembly standards.

Direct factory relationships often provide advantages including lower minimum order quantities, faster turnaround times, and better communication than distributor arrangements. However, verify manufacturing capabilities and quality systems before committing to important projects.

The custom engraved keychain market continues expanding as businesses recognize their promotional value and consumers embrace personalization trends. Understanding how to make engraved keychains with modern UV printing technology positions manufacturers to capitalize on these growing opportunities while delivering products that create lasting impressions and meaningful connections.