A custom corkscrew bottle opener is the hallmark of a sophisticated brand. It speaks to an audience that appreciates quality, detail, and the finer things in life. Unlike simpler open……

A bottle opener is a practical tool. But a custom wall bottle opener is so much more. It’s a statement piece for your home bar, a functional accessory for your restaurant’……

The Halligan tool is an icon. Forged from solid steel and wielded by firefighters and first responders, it represents unparalleled strength, reliability, and the power to force entry ……

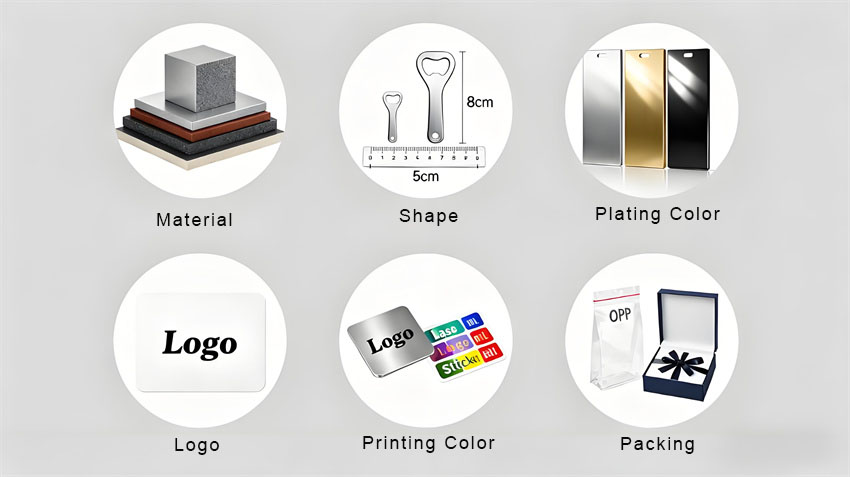

The idea of customizing your own bottle opener is exciting. Creating a unique promotional product that perfectly captures your brand’s spirit can significantly boost your visibi……

In the quest for marketing memorability, businesses face a constant challenge: how to make your contact information not just seen, but kept and used. The standard paper business card,……

In the world of promotional products, the ultimate goal is to find an item that is useful, constantly visible, and seamlessly integrates into your customer’s daily life. While m……

s you plan your special day, finding the perfect wedding favor that guests will actually love and keep can be a challenge. Move beyond traditional tre……

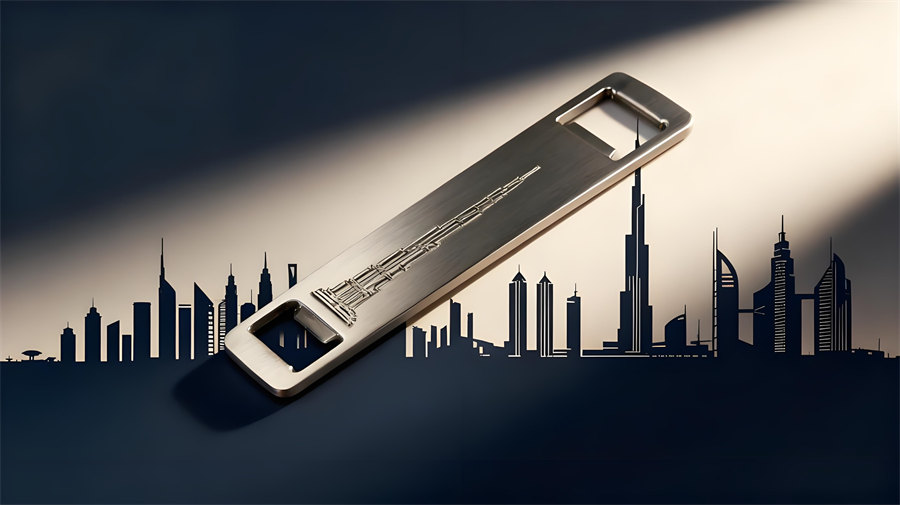

In the fast-paced world of bartending, speed, efficiency, and style are everything. Custom blade bottle openers are the ultimate tool for professionals and brands who want to make a s……

In an era of mass-produced goods, the warmth and authenticity of wood stand out. Custom bottle openers wood offer a unique blend of rustic charm, environmental sustainability, and pra……

For wine enthusiasts and brands alike, the ritual of opening a bottle is part of the experience. Customized wine bottle openers transform this everyday tool into a sophisticated brand……

Imagine a promotional product that lives on your customer’s fridge, used weekly and seen daily. A custom fridge magnet bottle opener combines two of the most useful household it……

Looking for a promotional item that combines safety, fun, and full-color branding? Look no further than a custom made soft PVC bottle opener. These flexible, durable, and incredibly c……

Tired of generic promotional items that get tossed in a drawer? It’s time to create a practical, memorable, and highly effective marketing tool. Custom shaped bottle openers are……

Uncap Memories: How to Create the Perfect Custom Engraved Bottle Opener Do you have a special memory that deserves to be celebrated every day? Maybe it’s a wedding day, a busine……

The Ultimate Guide to Choosing a Custom Engraved Bottle Opener Let’s be honest—we’ve all struggled with a flimsy bottle opener. Maybe it bent, maybe it broke, or maybe it ……

We’ve all been there. Staring at a shelf of generic greeting cards, scrolling through endless online gift lists, or panicking because someone’s special day is tomorrow and you have n……

PRODUCTS

Contact Us

Subscribe

Sign up for the latest product and event news

LINK: Linglark Seats stainless steel supplier Funny Shooter 2

Copyright @ 2026 Badge Artisans Co., Ltd

Our team will reply within 24 hours. Please check for emails from the domain badgeartisans.com.