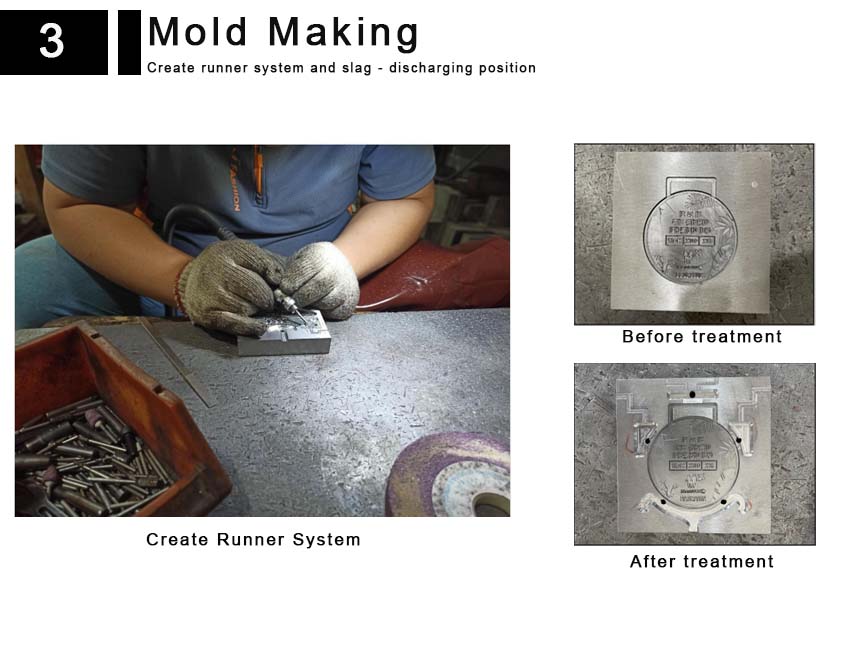

The process of creating a runner system (for feeding in alloy material), a slag – discharging position, and cooling water channels in the mold to facilitate the injection of alloy material into the mold for product formation.

Mold making – create runner system

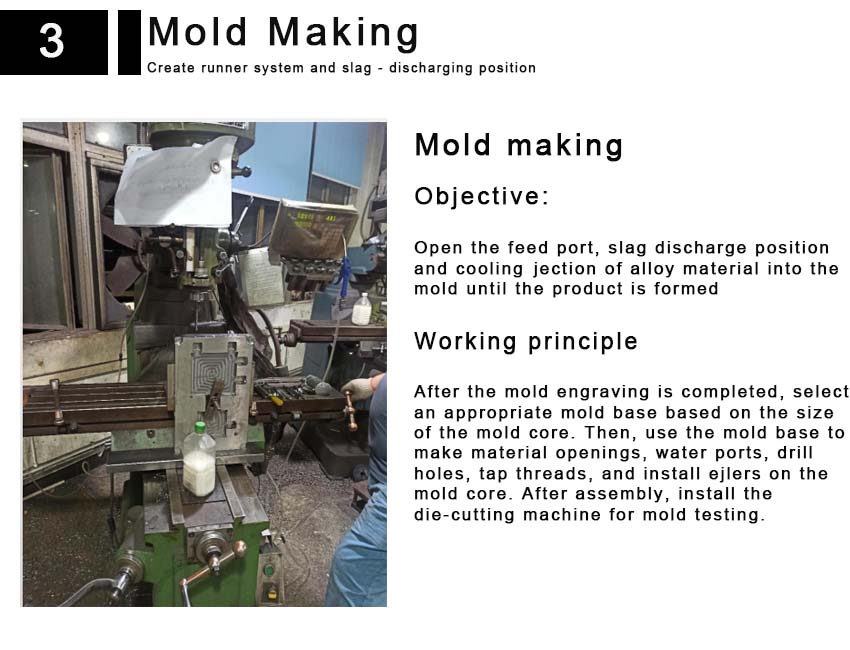

Mold making

Objective:

Open the feed port, slag discharge position and cooling water channel on the mold to facilitate the injection of alloy material into the mold until the product is formed

Working principle

After the mold engraving is completed, select an appropriate mold base based on the size of the mold core. Then, use the mold base to make material openings, water ports, drill holes, tap threads, and install ejlers on the mold core. After assembly, install the die-cutting machine for mold testing.

Mold making