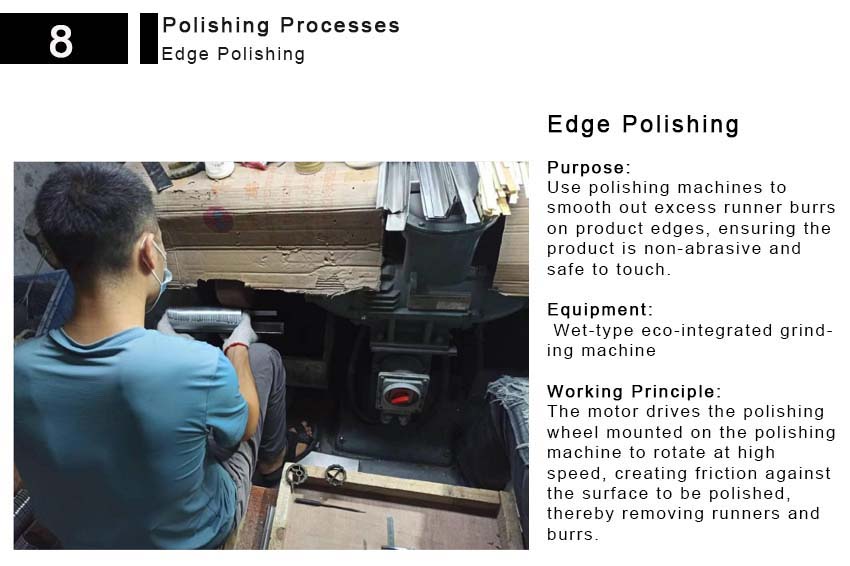

Edge Polishing

Purpose: Use polishing machines to smooth out excess runner burrs on product edges, ensuring the product is non-abrasive and safe to touch.

Equipment: Wet-type eco-integrated grinding machine

Working Principle: The motor drives the polishing wheel mounted on the polishing machine to rotate at high speed, creating friction against the surface to be polished, thereby removing runners and burrs.

polishing process edge polishing

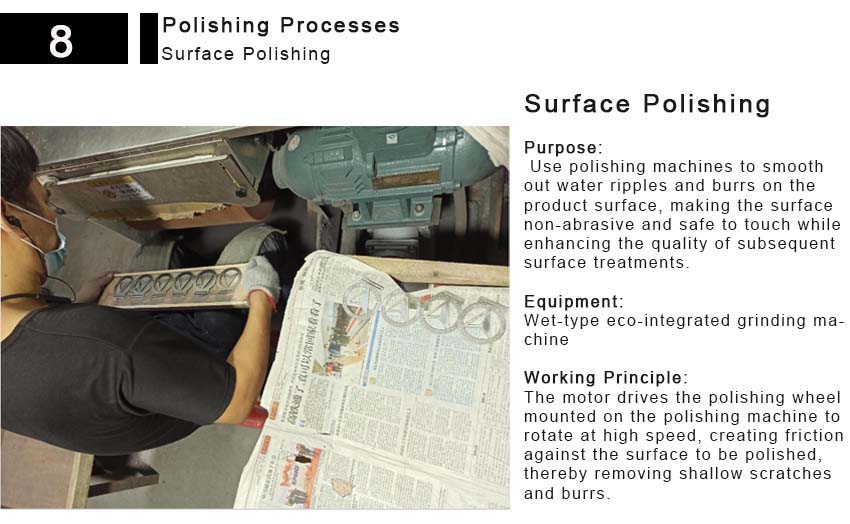

Surface Polishing

Purpose: Use polishing machines to smooth out water ripples and burrs on the product surface, making the surface non-abrasive and safe to touch while enhancing the quality of subsequent surface treatments.

Equipment: Wet-type eco-integrated grinding machine

Working Principle: The motor drives the polishing wheel mounted on the polishing machine to rotate at high speed, creating friction against the surface to be polished, thereby removing shallow scratches and burrs.

polishing process surface polishing

Auxiliary Polishing Tools

polishing process auxiliary polishing tools

Melon Wheel

With soft material, it is suitable for deburring the surface of electrophoretic sand-blasted products, antique brushed products, and three-dimensional products.

Abrasive Belt

Suitable for flattening flat surfaces of products and processing edge runners.

Nylon Wheel

With hard material, it is suitable for grinding product edges.

Hemp Wheel

Widely used for grinding and polishing metal products such as hardware, stainless steel, aluminum, and electroplated items. It is a common material for polishing machines.

Polishing Wax

Accelerates the entire polishing process and smooths the material surface.