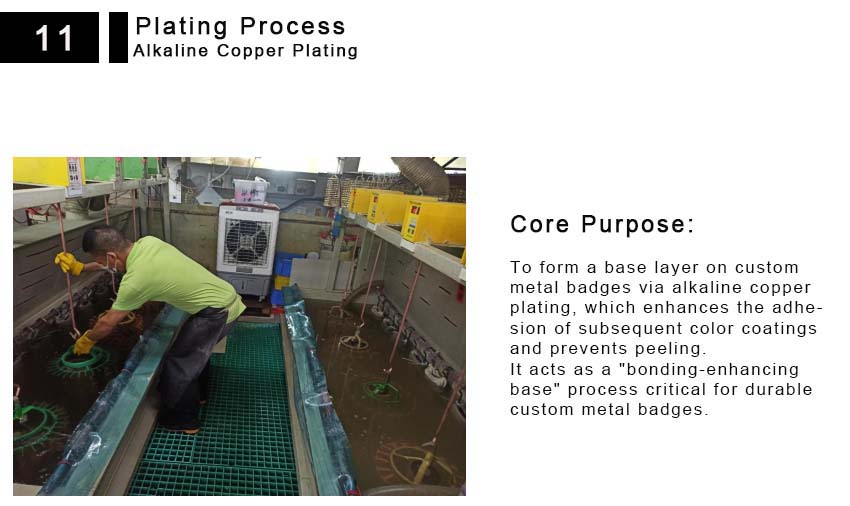

1. Alkaline Copper Plating

Core Purpose:

To form a base layer on custom metal badges via alkaline copper plating, which enhances the adhesion of subsequent color coatings and prevents peeling. It acts as a “bonding-enhancing base” process critical for durable custom metal badges.

Key Equipment:

Alkaline copper plating tank, specifically designed for an alkaline plating solution environment to suit the needs of custom metal badge production.

Working Principle:

1. Electrolytic Device Composition: Consists of a low-voltage, high-current power supply, alkaline plating solution, the custom metal badge to be plated (cathode), and an anode.

2. Plating Solution Components:

– Main salt (provides copper ions);

– Complexing agent (forms complexes with copper ions to stabilize their form);

– Buffer (maintains the stable pH value of the solution).

3. Deposition Process:

Under the action of an external electric field, copper ions in the plating solution are reduced to copper atoms, uniformly deposited on the surface of custom metal badges to form a base layer. This is similar to “laying a foundation” for subsequent color coatings on custom metal badges, ensuring long-term adhesion.

alkaline copper plating

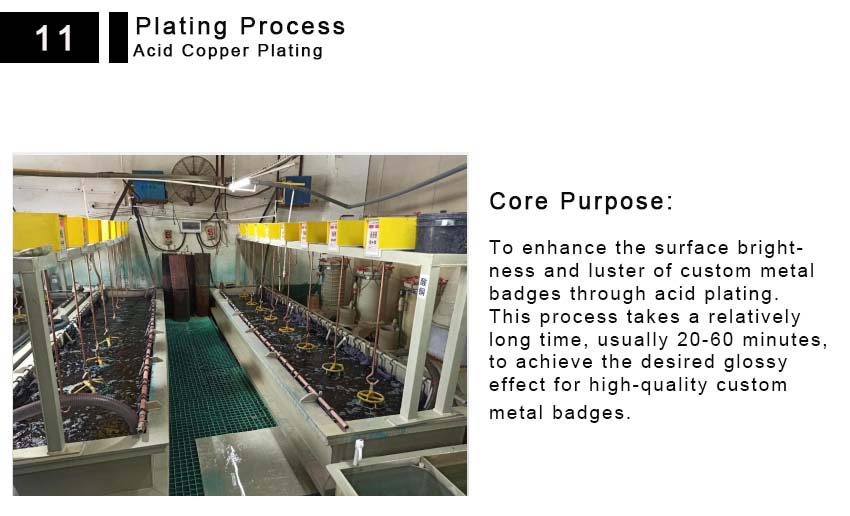

2. Acid Copper Plating

Core Purpose:

To enhance the surface brightness and luster of custom metal badges through acid plating. This process takes a relatively long time, usually 20-60 minutes, to achieve the desired glossy effect for high-quality custom metal badges.

Key Equipment:

Acid copper plating tank, adapted to an acidic plating solution environment for refining the surface of custom metal badges.

Working Principle:

1. Electrolytic Device Composition: Similar to the alkaline copper plating process, it consists of a power supply, acidic plating solution, the custom metal badge (cathode), and an anode.

2. Plating Solution Components:

– Main salt (provides copper ions under acidic conditions);

– Complexing agent (adapts to the acidic environment and stabilizes copper ions);

– Buffer (adjusts the pH value of the acidic solution).

3. Deposition Process:

Copper ions are reduced and deposited under the action of an electric field. Meanwhile, the acidic environment promotes tighter and more uniform arrangement of copper atoms, forming a mirror-like glossy surface on custom metal badges—similar to the effect of “polishing and glazing” to elevate the visual appeal of custom metal badges.

3. Comparison Table of Core Differences

| Comparison Dimension | Alkaline Copper Plating | Acid Copper Plating |

|---|---|---|

| Process Positioning | Base layer for custom metal badges (enhances adhesion) | Surface layer for custom metal badges (improves gloss) |

| Plating Solution Property | Alkaline (higher pH value) | Acidic (lower pH value) |

| Processing Time | Usually shorter (depending on base thickness needs for custom metal badges) | 20-60 minutes (sufficient deposition for gloss on custom metal badges) |

| Core Function | Improves subsequent coating adhesion on custom metal badges, prevents peeling | Gives a mirror-like gloss to custom metal badges, enhancing aesthetics |

| Typical Application Scenarios | All custom metal badges requiring multi-layer plating (e.g., base for gold/nickel plating) | Custom metal badges needing high-gloss effects (e.g., mirror copper, decorative plating) |