Electrophoresis

Blackening is a common chemical treatment for metal surfaces. It forms an oxide film on the surface of custom made police badges to isolate them from air, thereby achieving rust resistance. Notably, custom made police badges with electrophoresis finishes like vintage tin, vintage gold, vintage bronze, or vintage red copper all require blackening treatment using blackening solution to perfect their vintage effect.

Together, electrophoresis and blackening are key processes in crafting the unique vintage appeal of custom made police badges, balancing both aesthetic depth and long-term durability.

Electrophoresis Colors:

Common options for custom made police badges include vintage tin, vintage gold, vintage bronze, vintage red copper, matte black, and glossy black—each contributing to distinct classic or tactical aesthetics.

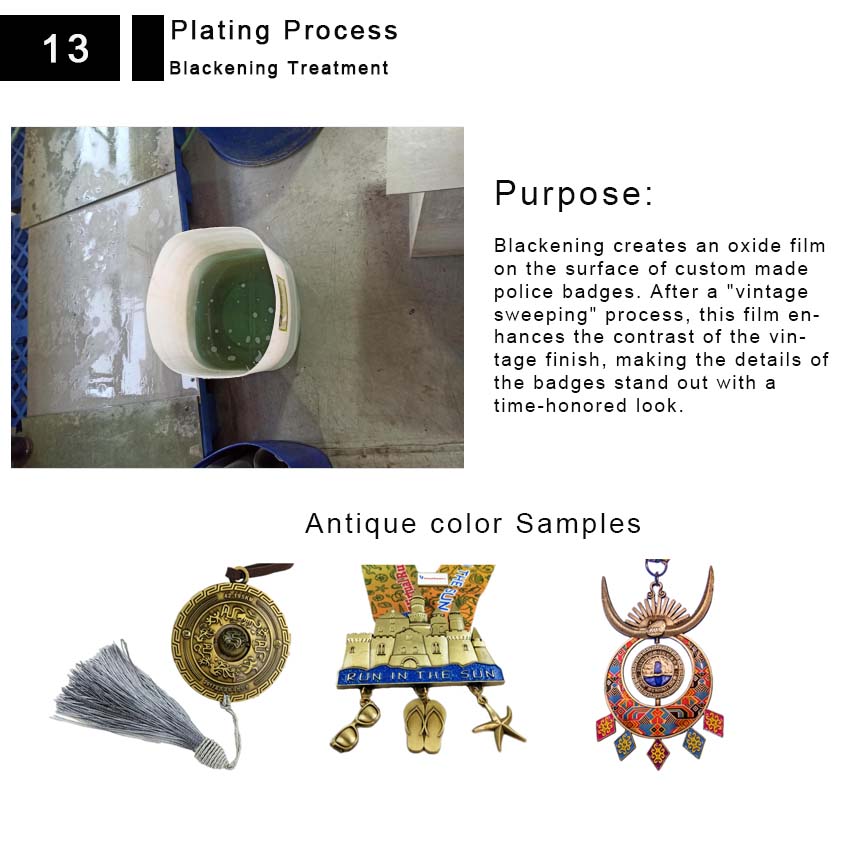

Blackening Treatment Purpose:

Blackening creates an oxide film on the surface of custom made police badges. After a “vintage sweeping” process, this film enhances the contrast of the vintage finish, making the details of the badges stand out with a time-honored look.

blackening treatment

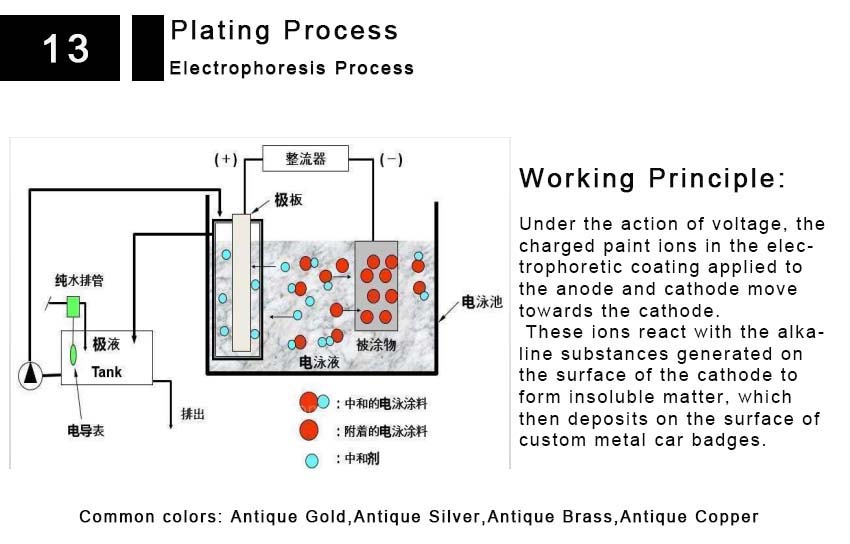

Working Principle:

Under the influence of voltage, charged paint ions in the electrophoretic coating applied to the anode and cathode move toward the cathode. These ions react with alkaline substances generated on the cathode surface to form insoluble matter, which then deposits evenly on the surface of custom made police badges.

electrophoresis process