The True Cost of Custom Engraved Medals: 5 Price Drivers Your Procurement Team Needs to Know

If you are responsible for managing large-volume purchases for annual events, athletic leagues, or corporate recognition programs, you know the frustration: receiving wildly different quotes for seemingly similar custom engraved medals. When dealing with significant organizational budgets, these discrepancies can easily derail your planning and lead to unwelcome surprises.

This comprehensive guide is designed to bring clarity to your purchasing process. We will reveal the five core factors that determine the final price of your bulk custom medal order, helping your team achieve budget transparency and predictable cost control for your organization’s awards.

1. Core Driver One: The Tooling Fee (The One-Time Investment)

The single biggest cost shock for those ordering customized awards for the first time is often the tooling fee, sometimes referred to as the mold fee. This is the one-time, upfront cost required to transform your digital design into a physical steel or aluminum mold used for casting the metal components of your medal.

high-precision molds-engrave-making

How This Impacts Your Organizational Budget:

-

Long-Term Value: While the initial outlay can be substantial, the mold fee makes subsequent re-orders significantly cheaper, as this charge is waived. You are essentially investing in a manufacturing asset for future use.

-

Design Complexity: The cost of the mold is directly proportional to the complexity of your design. Intricate 3D relief, unique cut-outs, or non-standard shapes require more sophisticated, and therefore more expensive, tooling.

Purchasing Tip: To maximize cost efficiency, consider creating a reusable “core medal” mold that features your organization’s permanent logo or emblem. You can then use the cost-effective engraving process to customize variable elements like dates, tiers, or categories.

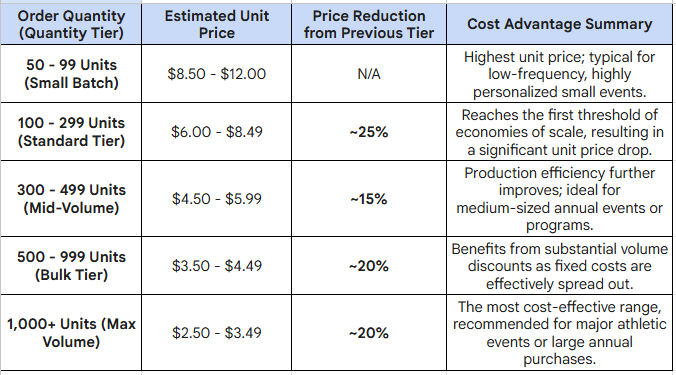

2. Core Driver Two: Order Volume (The Economy of Scale)

the unit price decreases as the order quantity increases.

The golden rule in custom medal manufacturing is simple: the unit price decreases as the order quantity increases. This is due to the manufacturer’s fixed costs. Whether the factory floor sets up a machine to stamp 100 medals or 1,000, the machine setup and labor time are largely similar.

Analyzing Your Tiers:

-

Price Breakdowns: Suppliers typically offer clear price breaks at specific volume thresholds (e.g., 100, 300, 500, 1,000+ units). Understanding where these tiers fall can help you make minor adjustments to your order size for significant savings.

-

Predictive Ordering: If your organization hosts multiple annual events, or if you run a multi-stage league, procuring your predicted annual quantity in a single bulk order will dramatically lower the per-unit cost compared to placing several small, individual orders throughout the year.

3. Core Driver Three: Materials and Dimensions (The Basic Build Cost)

Medals-in-Different-Colors

The fundamental cost of your award is rooted in its size, weight, and the material from which it is cast.

Material Comparison and Cost:

-

Zinc Alloy: The most common and cost-effective material. Highly versatile, it is ideal for complex 3D detailing and large orders.

-

Brass/Copper: A premium option. These materials are heavier and offer a superior, high-end feel, but they come at a higher unit cost and are usually reserved for high-level recognition or VIP awards.

-

Dimensions: The medal’s diameter and thickness directly dictate the amount of raw material required. A medal that is 3 inches wide and 5mm thick will logically cost more than a 2-inch, 3mm thick medal.

Purchasing Tip: Look for opportunities to balance quality and budget. Many organizations use brass for their gold-tier winners to elevate prestige, while using high-quality zinc alloy for the silver and bronze tiers to control the overall award budget without compromising visual appeal.

4. Core Driver Four: Custom Engraving and Finishing Processes (The Value Add)

plating chart

The term “custom engraved medals” covers a variety of finishing techniques, and the one you choose significantly impacts the final price.

Engraving Cost Breakdown:

-

Mechanical vs. Laser Engraving: Mechanical engraving creates a deep, traditional cut, while laser engraving is faster and often used for high-volume personalization. If your supplier includes free, unlimited engraving as part of their service, this is a major advantage that eliminates a variable cost that frequently concerns award managers.

-

Enamel (Color) Work: Medals with multiple enamel colors, especially those requiring precise application (like hard enamel), are more expensive than those using a single-color or simple plating.

-

Plating Effects: Costs vary between standard finishes (shiny gold/silver/bronze) and premium finishes like antique plating, two-tone plating, or specialized matte finishes.

5. Core Driver Five: Attachments and Presentation (The Final Touches)

premium gift packing

Don’t overlook the costs associated with the presentation of your medals. These details can elevate the recipient experience but must be factored into the overall unit cost.

Ribbons and Lanyards:

-

Plain vs. Custom Printed: A simple stock ribbon is cost-effective. A ribbon that is custom-dyed or imprinted with your organization’s logo and event date will incur an additional setup and per-unit printing cost.

-

Attachments: Specialty attachments, like custom clasps or buckles, add to the hardware cost.

Packaging Upgrades:

-

Basic packaging (individual polybags) is usually free. Upgrading to presentation options—such as velvet boxes, acrylic display cases, or custom-branded envelopes—will significantly increase the per-unit price, though they dramatically boost the award’s perceived value.

Achieving Budget Certainty for Your Awards Program

For professionals managing large-scale purchasing, understanding these five factors is the key to predictable budgeting. A reputable supplier of custom engraved medals will provide a quote that clearly itemizes the tooling, material, and process costs, ensuring your team avoids hidden fees and unexpected charges.

By focusing on volume efficiency, strategic material choices, and leveraging cost-saving engraving solutions, your organization can procure premium, high-impact recognition medals without ever compromising on quality or exceeding your financial targets.

We invite you to reach out to our specialists today. Let us help your team develop a detailed, cost-transparent bulk quotation tailored specifically to your organization’s needs and goals.