Introduction: Your Brand’s First Impression—Made Magnetic

A name badge isn’t just a tiny piece of plastic or metal; it’s often the very first thing your clients or customers notice about your employees. If you’re still dealing with the hassle of pin-backed badges that ruin expensive corporate wear, or cheap badges that fade quickly, you know it’s time for an upgrade.

Custom magnetic name badges with logo are the smart, professional solution. They look sharper, feel more substantial, and, most importantly, they protect your team’s uniforms. But ordering the right badge in bulk means knowing the details—from the material it’s made of to the way your colors are printed. This guide, written from a manufacturer’s perspective, will walk you through the key decisions to ensure your next badge order is flawless.

Part I: What Your Badge is Made Of: Quality, Durability, and Feel

The right material and the coloring technique you choose set the tone for your badge’s appearance and how long it lasts. It’s a balance between luxury, longevity, and your budget.

1. Badge Body Materials: Premium vs. Practicality

Badge-Body-Materials-Zinc-Alloy-vs-PVC

-

Zinc Alloy (For the High-End Look): If your company culture calls for a weighty, incredibly durable, and sophisticated accessory—perfect for executives, hospitality, or luxury retail—Zinc Alloy is your top choice. This material is crucial for achieving complex, multi-layered designs through the die-casting process, resulting in a smooth, high-end feel that plastic simply cannot replicate.

-

PVC/Acrylic (For Flexibility and Volume): If you manage a large workforce, have a tight budget, or require badges where employee names and titles might change often, lightweight PVC or Acrylic is more practical. It allows for quick, high-volume production.

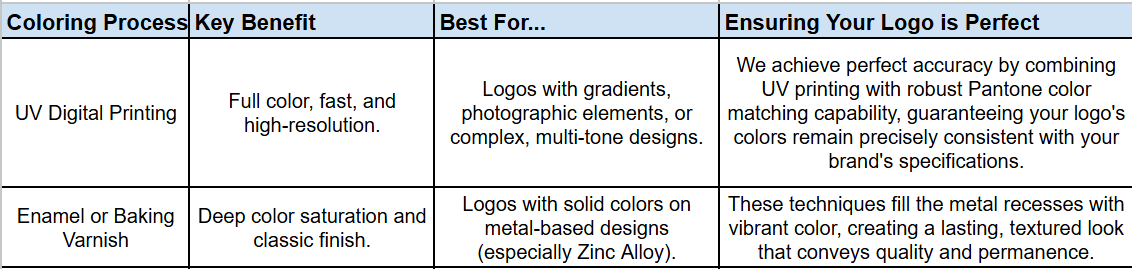

2. Bringing Your Logo to Life: Mastering Color Consistency

badge-coloring-process-UV-printing-vs-enamel

The integrity of your brand’s logo is non-negotiable. You need absolute confidence that the colors on your finished badges will precisely match your company’s established brand standards.

Coloring Process

Part II: The Magnetic Difference: Security, Comfort, and Care

Switching to a magnetic name badge with logo solves the major problem of uniform damage. However, you also need to know that the badge will stay put and be comfortable for your team.

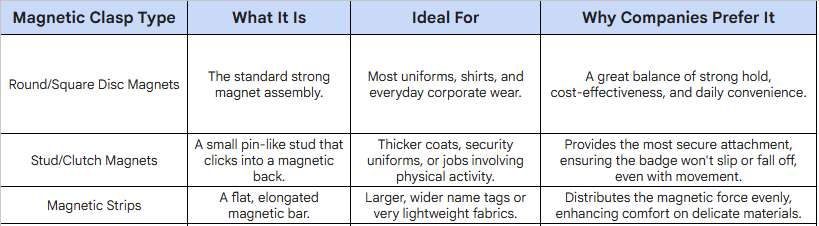

1. Choosing the Right Magnetic Clasp

Choosing-the-Right-Magnetic-Clasp

We offer three trusted magnetic solutions, each designed to perform reliably on different types of corporate attire:

Choosing the Right Magnetic Clasp

2. A Note on Safety and Placement

The greatest benefit of a magnetic badge is that it protects expensive corporate uniforms from punctures and tears. Just a couple of simple guidelines are helpful for your employees:

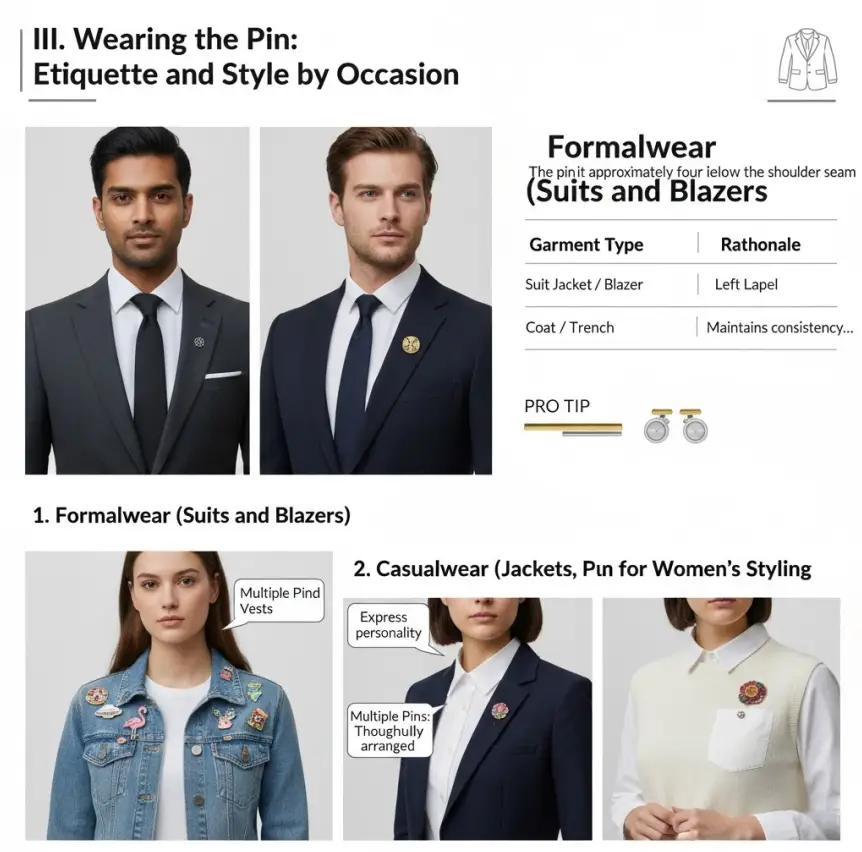

Wearing the Pin Etiquette and Style by Occasion

-

Placement: The best spot is usually the upper chest pocket area or the lapel.

-

General Awareness: While modern magnets are very safe, employees should be advised to wear the badge away from sensitive devices, such as pacemakers.

Part III: Getting Your Order Right: A Simple Guide to Quality Control

When you’re preparing a large order for magnetic name badges with logo, your focus should be on ensuring consistent quality across the batch.

1. Your Customization Checklist

custom-challenge-coins-production-process

Before you commit to a major order, make sure you take these critical steps:

-

Color Verification: Insist on approving proofs that specifically reference Pantone Color codes for your logo. This is your best defense against color drift and guarantees your brand integrity.

-

Sample Production: If time allows, ask to see a physical sample made with the exact material (e.g., Zinc Alloy) and the actual coloring process (e.g., UV Print). Seeing a final product is invaluable before mass production begins.

-

Clear Timelines: Get a firm commitment on the turnaround time for the production—especially for complex die-casting—and shipping, so your team is never left waiting.

By partnering with an experienced source, you benefit from our direct control over every step—from die-casting to the final UV printing and magnetic assembly. This streamlines the process, guarantees high quality, and ultimately ensures the custom magnetic name badges with logo you receive are a perfect, professional representation of your company.