Question: What is the role of acid copper plating? Answer: Enhances product gloss and smoothness. Critical for achieving premium finishes in custom orders.

Question: What equipment is used for degreasing in electroplating, and its principle? Answer: Ultrasonic cleaning machine. Generates high-frequency vibrations to emulsify and remove o……

Crafting Excellence: Why Die Cast Medals Are the Superior Choice for Your Custom Awards I. Introduction: The Critical Choice in Custom Award Crafting Every exceptional event o……

Question: Why does electroplating blistering occur? Answer: Incomplete pre-cleaning or improper drying after electroplating/coating. Our factory employs ultrasonic cleaning and strict……

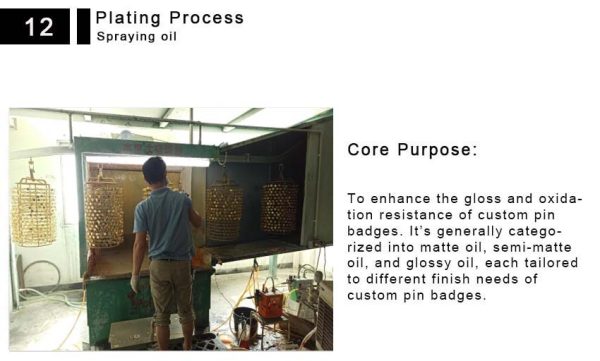

Question:What is the principle of spray painting? Answer: Compressed air atomizes liquid paint into fine droplets, evenly coating the product surface. Suitable for high-efficiency cus……

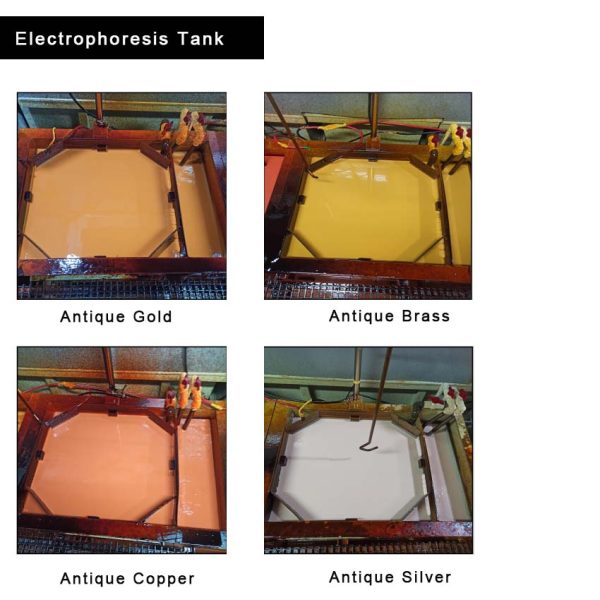

Question:What is the principle of electrophoresis? Answer: Charged paint ions migrate to the cathode under voltage, reacting with alkaline substances to form a non-soluble coating. Id……

Question: What is the principle of electroplating? Answer: Utilizes electrolysis to deposit a thin layer of metal or alloy onto a substrate surface. This enhances corrosion resistance……

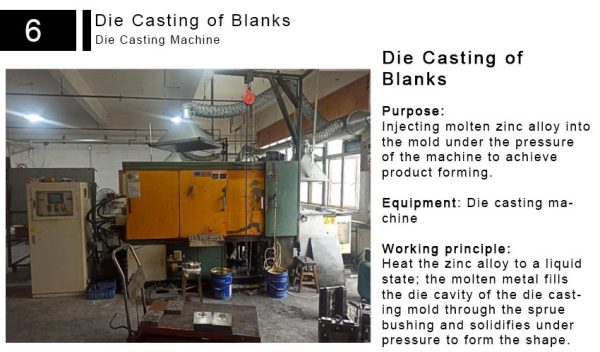

Question: Why do fine textures occasionally fail to form on the cast blank? Answer: Excessive release agent application blocks intricate details, preventing zinc alloy liquid from fil……

Elevate Your Sports Events with Custom 3D Engraved Medals Custom medals are the highlight of any athletic achievement. Our Personalized Sports Medals Design combines cutting-edge 3D……

Question: Why are sharp corners of the cast blank not fully formed? Answer: Insufficient die-casting machine pressure. Our factory selects appropriate tonnage machines based on produc……

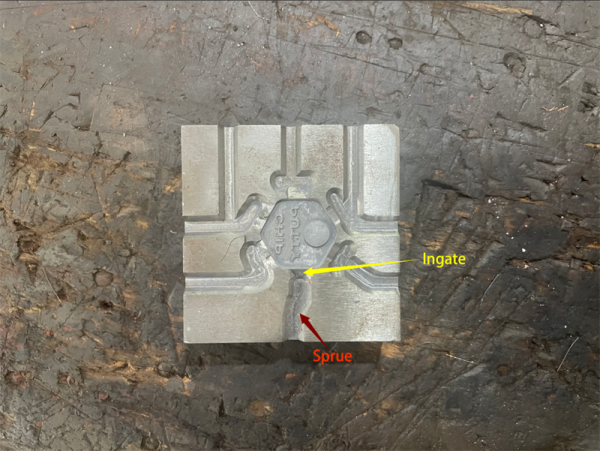

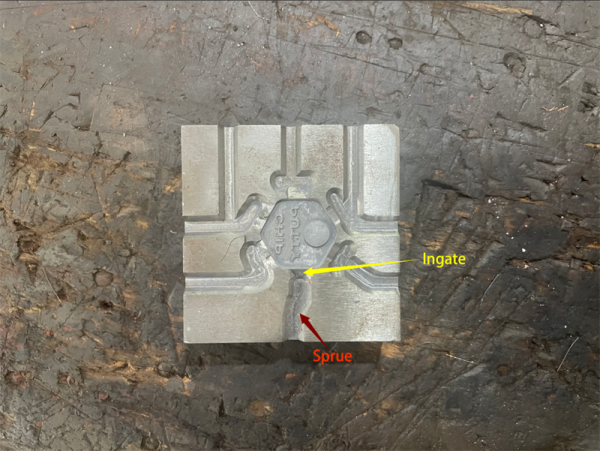

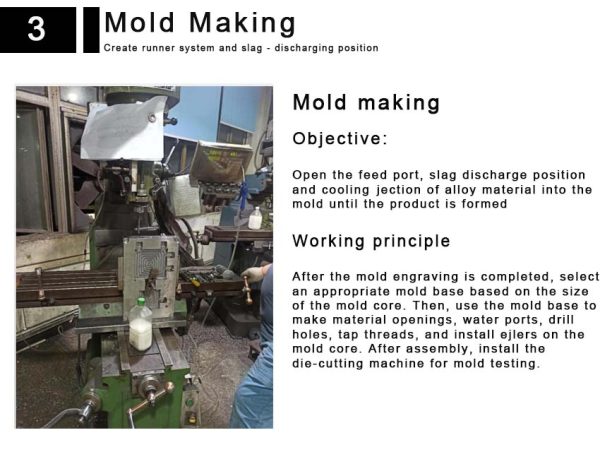

Question: How to determine sprue location in mold design? Answer: Based on product shape and size. For zinc alloy medals, sprues are typically evenly spaced at four positions around t……

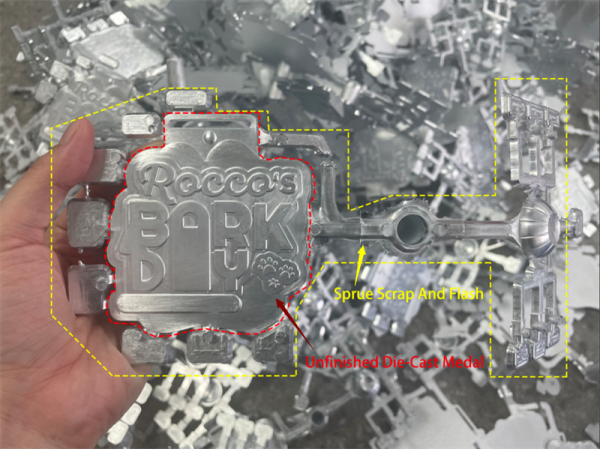

Question :Why remove sprue and flash from the cast blank? Answer: Sprue and flash are unnecessary by products of die-casting and must be cleaned and removed to meet custom product sta……

Question:What causes surface porosity on the cast blank? Answer: Poor mold venting. Adjust vent holes to improve exhaust efficiency. This is critical for maintaining high-quality cust……

Question: What causes water marks on the cast blank? Mold making Answer: 1. Insufficient mold surface finish; 2. Insufficient die-casting machine pressure; 3. Rapid startup speed caus……

Introduction In the competitive world of recognition and awards, the quality of your medals reflects the prestige of your event. Our custom award medals manufacturing service offers ……

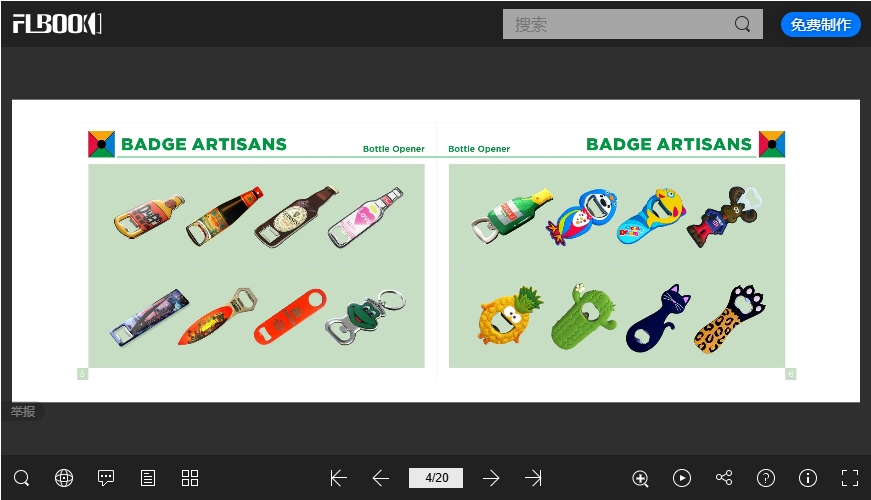

PRODUCTS

Contact Us

Subscribe

Sign up for the latest product and event news

LINK: Linglark Seats stainless steel supplier Funny Shooter 2

Copyright @ 2026 Badge Artisans Co., Ltd

Our team will reply within 24 hours. Please check for emails from the domain badgeartisans.com.